Cable tray roll forming machine line “One-Button Changeover”: How Smart Production Lines Are Remaking Cable Tray Manufacturing ?

“One-click model change”:the intelligent production line has improved the efficiency of cable tray manufacturing, and the theme “Efficient, Intelligent, and Green: How Cable Tray Forming Machines Drive the Upgrade of Infrastructure’s ‘Lifeline'”

This theme closely connects the equipment technology upgrade with national key development strategies such as new infrastructure, smart grids, and green buildings, enhancing the scope and practical significance of the report.

Integration and unification: Traditional punching and bending processes require multiple machines, resulting in low efficiency. The current trend is to develop composite machine tools that integrate punching, bending, and welding functions.

Green manufacturing and material innovation: With increasing national environmental protection requirements, equipment that can efficiently process environmentally friendly materials such as galvanized steel sheets and aluminum alloys is becoming more popular.

Market and Future Outlook: Under policies such as new infrastructure development, equipment manufacturing faces challenges related to customization and small-batch production, as well as digital transformation (remote operation and maintenance) and rapid model changes, which provide guarantees for achieving automation.

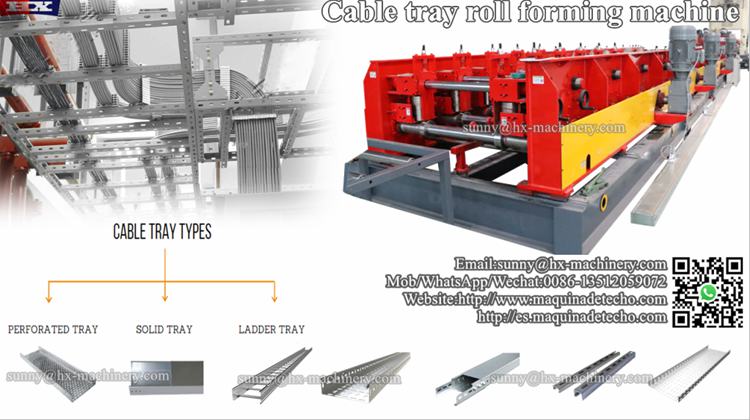

Classification of cable tray machines based on their applications:

| Ladder-type cable tray | (Ladder-type Cable Tray Roll Forming Line) | Open structure, excellent heat dissipation. The production line focuses on the rapid and continuous production of side rails and crossbars, making it a mainstream choice for power and communication engineering projects. |

| Trough/Tray type cable tray | (Trough-type Cable Tray Roll Forming Line) | Closed/semi-closed structure, dustproof and shielded. The production line is designed for one-time molding of U-shaped channels, suitable for data centers, office buildings, and other places with high requirements for cable protection. |

| Large-span heavy-duty bridge structure | Heavy-duty / large-span bridge structure forming production line | The equipment has high structural strength and powerful forming force. It is specifically designed for producing cable trays with large thickness (such as >2.0mm), wide width, and high load-bearing capacity, suitable for large-span applications such as factories and power plants. |

| Special material cable trays | (FRP Cable Tray Hydraulic Molding Press) | Non-metallic and corrosion-resistant. Manufactured by one-time compression molding using a mold under high temperature and high pressure, it is used in highly corrosive environments such as chemical and marine industries. |

Returning to core values, the upgrade of cable tray forming machines essentially provides more reliable and efficient structural support for the “circulatory system” of China’s infrastructure.