aluminum coil slitting machine is designed to efficiently cut aluminum coils into precise widths, making it ideal for a variety of industries. It handles a wide range of coil thicknesses, ensuring smooth, clean edges and high-quality results. With adjustable settings, the machine provides flexibility to meet specific cutting requirements. Operating at high speeds, it significantly boosts production efficiency while minimizing material waste.

| Main parameters of aluminum coil slitting machine | |

| Raw materials grade | Galvanized steel coil/Cold rolled coil/Color coil |

| Raw materials thickness | 0.3~3.0mm |

| Raw materials width | 1250mm |

| Raw materials inner diameter | Φ508mm/610mm |

| Raw materials outer diameter | ≤Φ1500mm |

| Raw materials coil weight | 5Tons |

| Slitting speed | 0~25m/min(During normal work) |

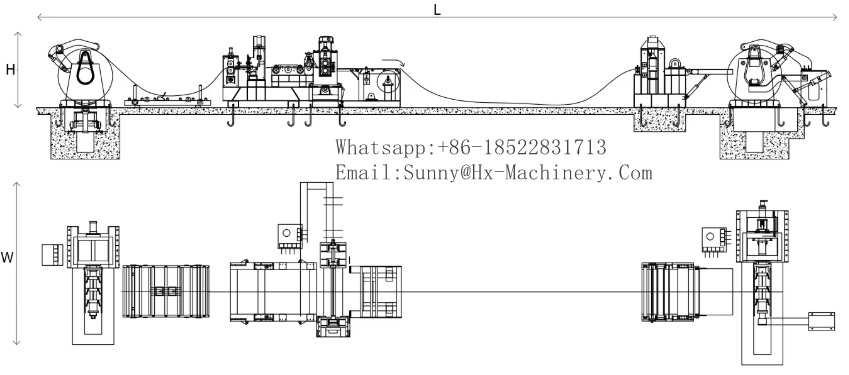

| Land occupation area | About 35m×5m |

This line mainly includes: hydraulic uncoiler, slitter and cutter, conveyor, hydraulic recoiler, or with roll forming machine,etc.

Some parts of the machine:

| A.Decoiler

Single cantilever structure bearing capacity 5Tons Support range:470-530mm hydraulic tension electric unwinding power:5.5KW frequency conversion and main motor 5.5KW Hydraulic pump 4KW

|

| B.Leveling

Hydraulic shovel head with two shaftsand total 11rollers(Up 5rows ,down 6rows ) roller diameter 90mm

|

| C.Slitting

slitting roll diameter 140mm-160mm Blade tool outer diameter 240-260mm Main motor power :7.5KW

|

| D.Damping

Double cylinder diameter 80mm Main frame use 10 mm thick iron plate welding Upper and Down iron plates with a thickness of 14 mm

|

| D.Collect waste

Power 2.7Kw*1set

|

| E. Hydraulic re-decoiler with coil car

|

And also our company has rich experience in the export field and exports to many countries around the world. We have a complete after-sales service system, and we will also give the corresponding instructions for the purchase of our products

With our customer:

Click to get more information about our machine and a more favorable price!