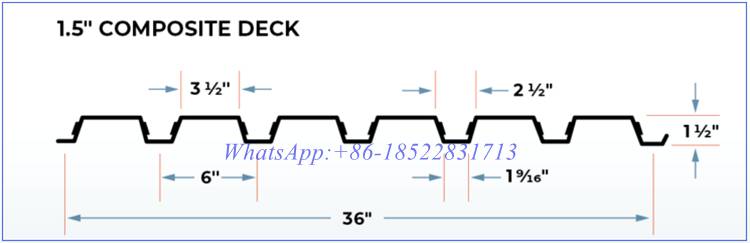

1.5” Composite deck b decking roll forming machine is one of equipment used in the manufacturing and construction industry to produce B Deck profiles. B Deck is a type of corrugated metal decking that is commonly used as a structural component in roofing and flooring systems. It provides support and stability to buildings and is often used in commercial and industrial construction projects.

1.5” Composite deck b decking roll forming machine technical details :

| No. | 1.5” Composite deck b decking roll forming machine | |

| 1 | Suitable to process | Alu-zinc steel coil/Galvanized steel coil |

| 2 | Rollers | 27 rollers or according to final design |

| 3 | Dimensions | 14.5*1.8*2.0m |

| 4 | Motor Power | 15Kw*2 |

| 5 | Pump Station Motor | 4Kw,Lichao |

| 6 | Thickness of the plate | 0.8-1.5mm |

| 7 | Productivity | 10-15m/min |

| 8 | Material of the cutting blade | Cr12Mov,Quenched treatment 58℃-60℃ |

| 9 | Diameter of the roller | Φ90mm |

| 10 | Weight | About 13500kgs |

| 11 | Main structure of the machine | 450 H Beams |

| 12 | Processing precision | Within 1.0mm |

| 13 | Side panel of machine | 20mm |

| 14 | Chain Wheel and Cycle Chain | 2 Inch |

| 15 | Voltage | 380V 50Hz 3phases or as customer’s need |

| 16 | Control system | PLC control (Delta) |

| 17 | Frequency system | Delta |

| 18 | Drive mode | Gear driver |

| 19 | Touch screen | Delta |

| 20 | Rolling materials | 45# forging steel with chromium plate |

| 21 | Length Tolerance | ±2mm |

1.5” Composite deck b decking roll forming machine each parts photos showing

1.5” Composite deck b decking roll forming machine packages and loading

A.The main body of machine with water-proof plastic, then fixed to container by 8mm diameter steel wire and angle iron.

B.Rollers and shafts are covered with anti-rust oil.

C.PLC control system and motor pump are packed with waterproof paper and plastic film.

D.Spare parts in a carton box.

E.Manual decoiler was nude packing.

F.The output-table put into a carton box.

G.If the machine is too long, we will divide it into two parts and pack them in one package with steel wire

OUR ADVANTAGE

Excellent after-sales service

A. 24 Hours online support B. Free supply of spare parts C. Provide on-site training for engineers

Machine customization

Metal tile profile, Machine color, Localization of operating language and voltage, Logo design, Machine protective cover.

Inspection report

Machine inspection reports of international certification institutions, such as Bureau Veritas, are available.