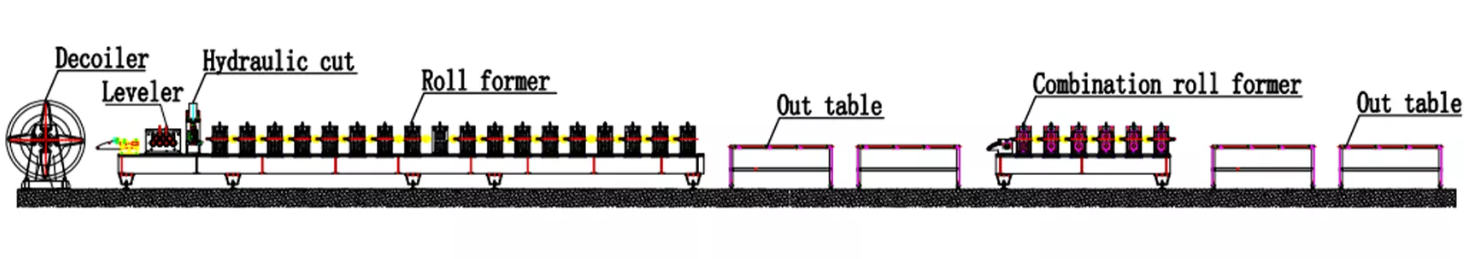

Box beam machine: The machine is designed to efficiently produce high-quality box beams for structural and construction applications. With advanced roll forming technology, it ensures precise and durable beams with consistent dimensions. Ideal for use in bridges, buildings, and industrial structures, this machine offers high productivity, easy operation, and minimal waste. Whether for small or large-scale production, the machine delivers cost-effective solutions for manufacturers looking to meet growing demand in the construction industry.

Production Process: Passive discharge—Leveling—Forming—Servo tracking cutoff—Discharge

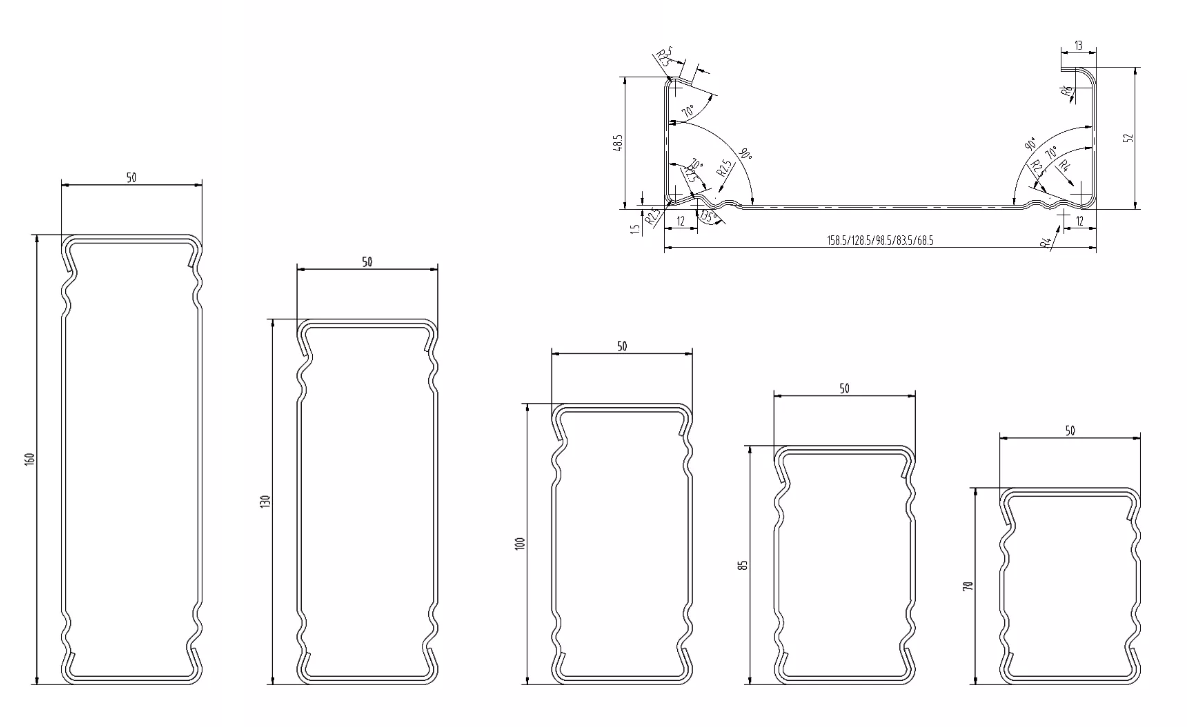

Box beam machine Drawing Model:Bottom:80-160mm technical details :

Beam roll forming machine manufacturers parameters |

||

|

||

| 1 | Equipment area | About 35*1.5*1.5m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 450-950 mm |

| 7 | Rolled strip thickness | 1.5(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Q235 cold rolled strip steel,galvanized coil |

| 9 | Rolling workpiece length | 2000-6000 mm |

| 10 | Produce speed | 6-12m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 25KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±1.5mm |

Box beam machine manufacturers detailed images for reference

| A.Uncoiler Decoiler

1. Maximum load-bearing capacity: 3T

|

| B.Leveling servo feeding machine

1.5 roller leveling

|

| C.Roll forming part

1. Shaft diameter φ65mm

|

| D.Discharging platform

1. 3m platform

|

Perforated box beam machine loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

Advantages of using a beam roll forming machine line for beam roll production include:

| High Precision | Ensures consistent dimensions and shapes for beams. |

| Material Efficiency | Minimizes waste and reduces production costs. |

| Automation | Reduces manual labor and errors, increasing production speed. |

| High Efficiency | Continuous operation speeds up production and shortens cycles. |

| Flexibility | Produces various beam sizes, adaptable to different racking systems. |

| Energy Saving | Reduces energy consumption and aligns with eco-friendly practices. |