Bracing machine c u channel bracing line:The Line is a high-performance, automated solution designed for the production of C and U-shaped bracing channels used in structural reinforcement and support systems. This advanced line ensures precision, efficiency, and versatility in manufacturing strong, reliable bracing components for a variety of applications, including construction, scaffolding, and industrial frameworks.

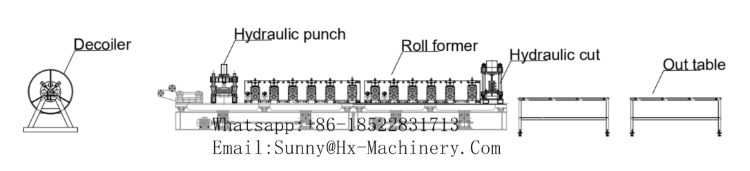

Forming Process: Discharge—Feed—Forming—Punching—Cutting—Discharge

Bracing machine Drawing Model:

| Bracing machine manufacturers parameters | ||

|

||

| 1 | Equipment area | About 15*1.5*1.6m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 450-950 mm |

| 7 | Rolled strip thickness | 1.0(±0.03)—1.6(±0.03) mm |

| 8 | Rolled strip material | Q235 cold rolled strip steel,galvanized sheet |

| 9 | Rolling workpiece length | 2000mm |

| 10 | Produce speed | 8-16m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 17KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±1.5mm |

Bracing machine manufacturers detailed images for reference

| A.Uncoiler Decoiler

1. Maximum load-bearing capacity: 2T

|

| B.Feeding

|

| C.Roll forming part

1. Shaft diameter φ65mm

|

| D.Punching

|

| E.Discharging platform

1. 3m platform

|

Perforated bracing machine loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

Advantages of using a bracing machine line for beam roll production include:

| High Precision | Produces accurate and consistent bracing profiles |

| Versatile | Can handle a variety of steel materials, including galvanized and cold-rolled steel |

| Customizable | Adjustable settings to create different bracing sizes and profiles |

| Energy-Efficient | Low power consumption for cost-effective and eco-friendly operation |

| User-Friendly | Easy-to-operate controls for quick setup and real-time monitoring |

| Energy Saving | Reduces energy consumption and aligns with eco-friendly practices. |