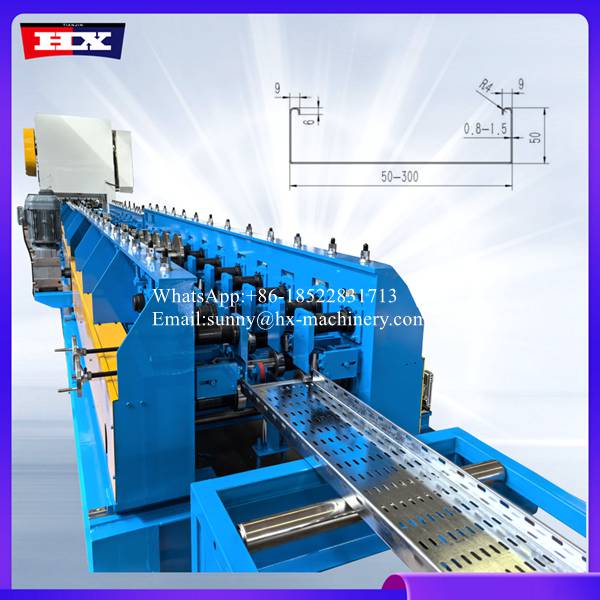

Cable tray cutting machine production line can roll steel products with a maximum thickness of 2.0mm, and can produce steel products with a base width of 50-300mm and a height of 50mm. Tolerances are required for length and width within ±1.5mm, and angles within 90°±3°.

Punch press process flow:

Active feeding —- Leveling servo feeding integrated machine —- Punch press (punching) —- Forming and cutting —- Unloading

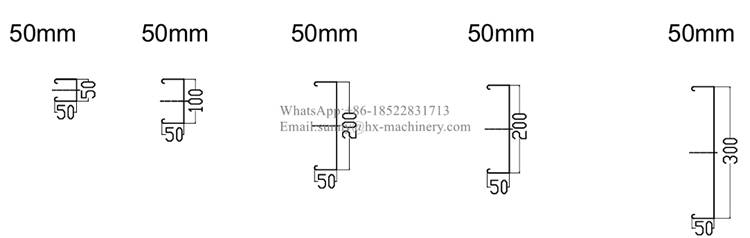

Cable tray roll forming machine manufacturers Drawing Model:Bottom:50-30 Waist high:50 technical details :

| Cable tray roll forming machine parameters | ||

|

||

| 1 | Equipment area | About 35×1.5×1.6m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 100-400 mm |

| 7 | Rolled strip thickness | 1.0(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Q235B cold rolled strip steel,hot rolled strip steel |

| 9 | Rolling workpiece length | 3000 mm |

| 10 | Online punching production speed | 6-8 m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 40KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±2mm |

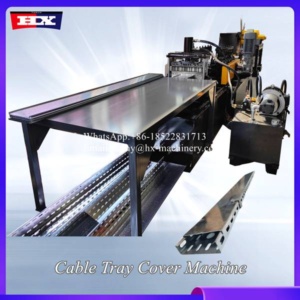

Cable tray cutting machine production line photos showing

Cable tray cutting machine production line loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

Why choose us?

| 1 | Complete after-sales service and technical support |

| 2 | Excellent performance and high-precision processing |

| 3 | High flexibility and versatility |

| 4 | Excellent reliability and durability |