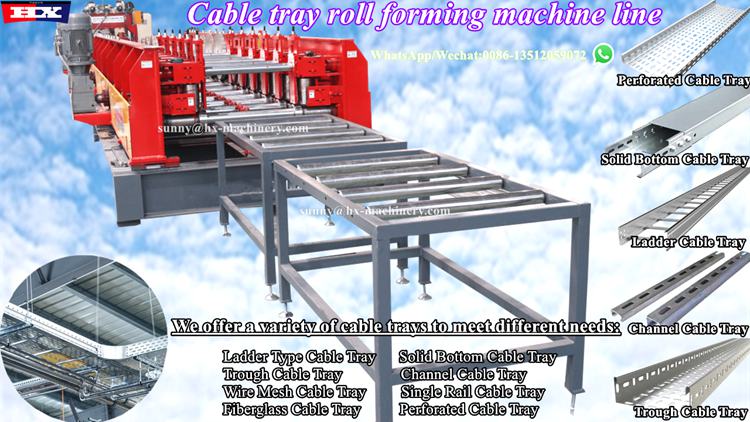

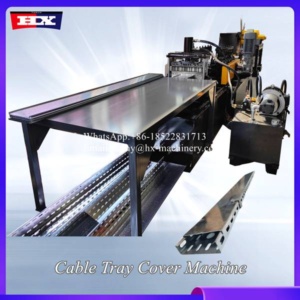

Cable tray making machine produced by our company, is used for producing cable trays that are used in all kind of factories and buildings. We offering you to Cable Tray Roll Forming Machine that comprise of efficient Punching Press, Hydraulic Press, Electric Control penel and many other Equipment, which make it an ideal option for many. The Cable Tray Roll Forming Machine can Manufacring a both superiority and quantity cable trays in less time.

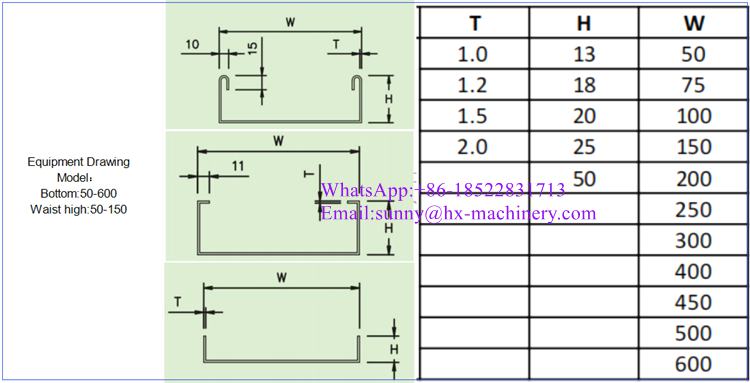

Cable tray making machine Drawing Model:Bottom:50-600 Waist high:60-200 technical details :

| Cable tray making machine parameters | ||

|

||

| 1 | Equipment area | About 38×1.5×1.6m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 450-750 mm |

| 7 | Rolled strip thickness | 1.0(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Q235B cold rolled strip steel,hot rolled strip steel |

| 9 | Rolling workpiece length | 3000 mm |

| 10 | Online punching production speed | 6-8 m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 40KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±2mm |

Cable tray making machine detailed images for reference

| A.6T Uncoiler Decoiler

1. Maximum load-bearing capacity: 6T

|

| B.Leveling servo feeding machine

1.8 roller leveling |

| C.200 Ton punching machine :200 Ton punching machine with servo feeding

|

| D.High-speed platform

1. Heavy-duty roller feed: 6 meters |

| E.Roll forming part

1. Shaft diameter φ65mm

|

| F.Discharging platform

1. 3m platform

|

About our company-TIANJIN HAIXING

We, Haixing Tianjin is a professional cold roll forming machine manufacturer,main machine includes roof roll forming machine,light keel roll forming machine, floor deck roll forming machine, purlin machine, leveling and slitting machine, metal fence roll forming machine, gutter roll forming machine, downspout roll forming machine, door frame machine, shutter door roll forming machine, highway guardrail roll forming machine, and other related construction equipment. We have extensive experience in the needs of different countries, such as profile drawing, operation languages, thickness range, instruction manual, installation, after-sales online support. Our equipment is mainly of medium and high configuration, such as famous brand PLC and Motor, Frequency converter, Long Service Life, Remote Control, Multifunctional, Energy saving.

Cable Tray Roll Forming Machine is for producing cable trays with pre-punched holes. The width of the cable trays is various.