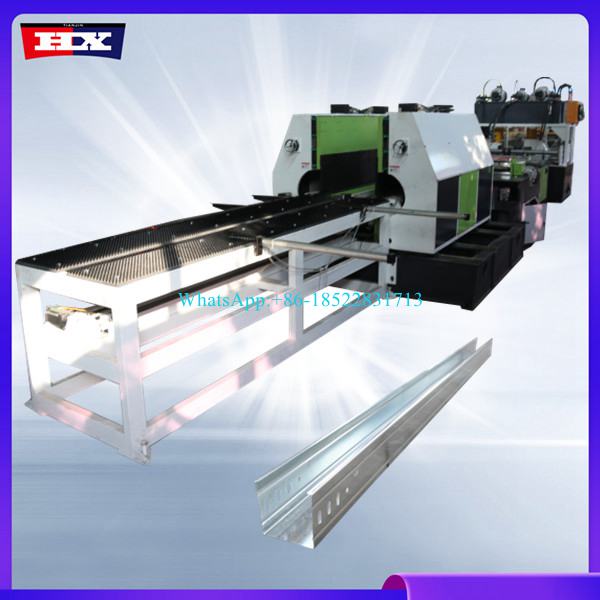

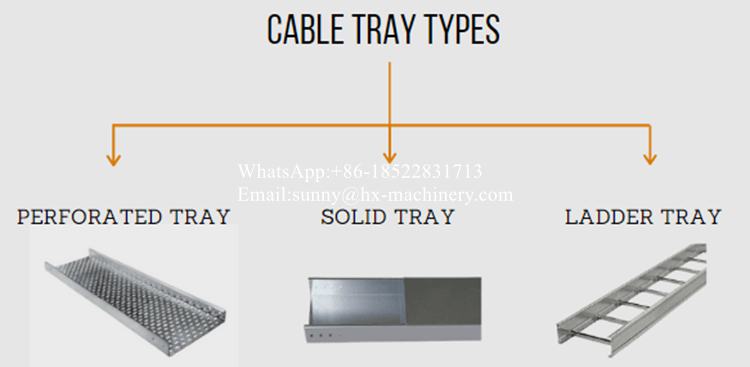

Cable tray manufacturing machine: We are Tianjin Haixing-design and manufacture of state-of-the-art roll forming machines, including machines for the production of cable trays. Our machines are highly efficient, use a continuous forming process, ensure consistent quality and are capable of producing complex profiles.

Our cable tray production line be used to produce cable tray,through exchange punching tooling to finish producing different specifications. One set of roller can make all specifications of cable tray. adjusting the width of roller to produce different width cable tray.

Cable tray roll forming machine Drawing Model:Bottom:100-600 Waist high:50-150 technical details :

| Cable tray manufacturing machine parameters | ||

| 1 | Equipment area | About 38×1.5×1.6m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 150-750 mm |

| 7 | Rolled strip thickness | 1.0(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Q235B cold rolled strip steel,hot rolled strip steel |

| 9 | Rolling workpiece length | 3000 mm |

| 10 | Online punching production speed | 6-8 m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 40KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±2mm |

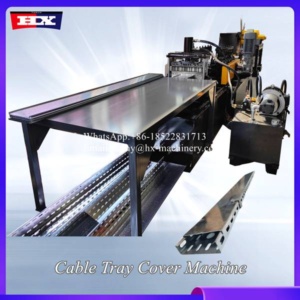

Cable tray manufacturing machine detailed images for reference

| 1 | 6T Uncoiler | 1. Maximum load-bearing capacity: 6T 2. Maximum roll width: 12-850mm 3. Inner diameter of roll: ф460-520 mm 4. Outer diameter of roll: ≤1600mm 5. Hydraulic tensioning, electric unwinding |

|

| 2 | Leveling servo feeding machine | 1.8 roller leveling 2. Leveling roller diameter: 90mm 3. Leveling motor: 4KW |

|

| 3 | 200 Ton punching machine | 200Tons Yangli press machine |  |

| 4 | Punching molds | Machine use the punching molds |  |

| 5 | High-speed platform | 1. Heavy-duty roller feed: 6 meters 2. Main motor power: 1.5KW 3. Electric opening and closing motor power: 0.37KW |

|

| 6 | Roll forming part | 1. Shaft diameter φ65mm 2. Shaft material 45# steel 3. Forming pass number 32 4. Main motor power 5.5KW×3 5. Automatic opening and closing motor 1.5KW×3 5. Roller material Cr12 6. Roller hardness HRC58-62 |

|

| 7 | Discharging platform | 1. 3m platform 2. Roller type 3. No power |

|

| 8 | Hydraulic station | Multiple solenoid valves Solenoid overflow valves Cooling system |

|

Cable tray manufacturing machine sales terms

●Payment Method

TT 30% as deposit ,balance payment after inspection while before delivery.

●Production Period:About 50-60 working days after the 30% deposit.

●Packing Method

Nude packing in the 40 feet container ,fixed well with oil rope, control cabinet and all the accessories with waterproof.

If you want use 40 feet container ,please advance tell us .

●Warranty:24 months limited warranty

Components and parts are free during warranty.

●Installation

If installation is needed, the seller will dispatch a technician to the buyer’s factory abroad to assist regulating the machine . The buyer should assist the seller to get the Chinese technician’s visa and should pay for the round trip air ticket ,local accommodation.and $150/day.

If installation is needed, the buyer shall make the following preparation before arrival of technicians.

*Position the machine in the buyer’s factory.

*Prepare necessary electric wiring.

*Prepare material of trial running.

*Provide labors for assistance and installation during installation.