Cable tray manufacturing machine price are reasonable.The Cable tray forming machine is the key equipment for producing cable tray. It has very distinct characteristics, which are mainly reflected in high efficiency, high precision, high degree of automation and flexibility.

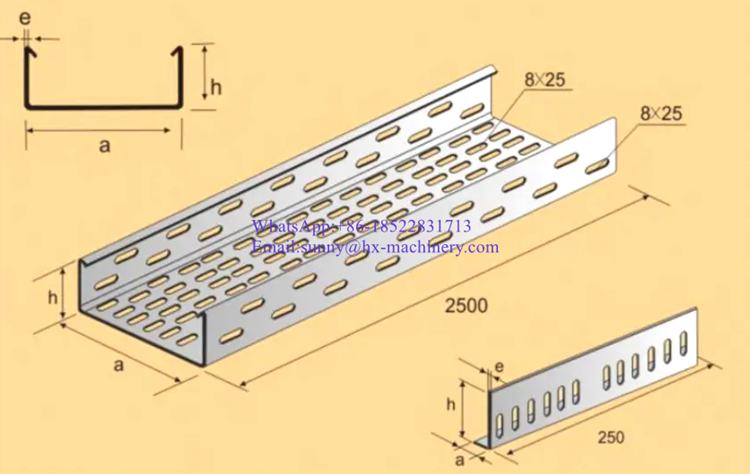

Cable tray manufacturing machine Drawing Model:Bottom:100-600 Waist high:50-200 technical details :

| Cable tray manufacturing machine price parameters | ||

|

||

| 1 | Equipment area | About 38×1.5×1.6m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 450-750 mm |

| 7 | Rolled strip thickness | 1.0(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Q235B cold rolled strip steel,hot rolled strip steel |

| 9 | Rolling workpiece length | 3000 mm |

| 10 | Online punching production speed | 6-8 m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 40KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±2mm |

Cable tray manufacturing machine pricedetailed images for reference

| A.5T Uncoiler Decoiler

1. Maximum load-bearing capacity: 5T

|

| B.Leveling servo feeding machine

1.8 roller leveling |

| C.200 Ton punching machine :200 Ton punching machine with servo feeding

|

| D.High-speed platform

1. Heavy-duty roller feed: 6 meters |

| E.Roll forming part

1. Shaft diameter φ65mm |

| F.Discharging platform

1. 3m platform

|

Cable tray manufacturing machine price loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

Core Features of Cable Tray Forming Machines

1. High Production Efficiency and Automation

Continuous Roll Forming: This is the most important feature. Through multiple passes (typically 10-20) of forming rollers, coiled material (such as galvanized sheet or stainless steel) is gradually and continuously bent into the designed cable tray cross-sectional shape (such as stepped, trough, or tray). This continuous process can achieve production speeds of 10-30 meters per minute, far exceeding traditional manual or segmented production.

Automated Assembly Line Operation: Modern cable tray forming machines typically integrate unwinding, leveling, punching/rivet punching, forming, cutting to length, and receiving. Requiring only one or two operators, the entire process, from coil loading to finished product output, is largely automated, significantly reducing manual intervention and labor intensity.

2. Extremely High Forming Accuracy and Consistency

Precision Roller Dies: The core component of the forming machine is the precision-engineered and machined rollers. These rollers ensure that each cable tray section is highly consistent in size, angle, and shape, fully complying with national standards or customer drawings.

Eliminating Human Error: Automated production completely eliminates dimensional deviations and irregular shapes caused by manual operations, ensuring product interchangeability and facilitating on-site installation.

3. Powerful Flexibility and Versatility

Multiple Uses: By replacing different roller dies and punching dies, a single forming machine can produce products of varying specifications, models, and heights.