Cable tray punching machine line punching process: decoil material-leveling-punchcand cut-forming –output of table

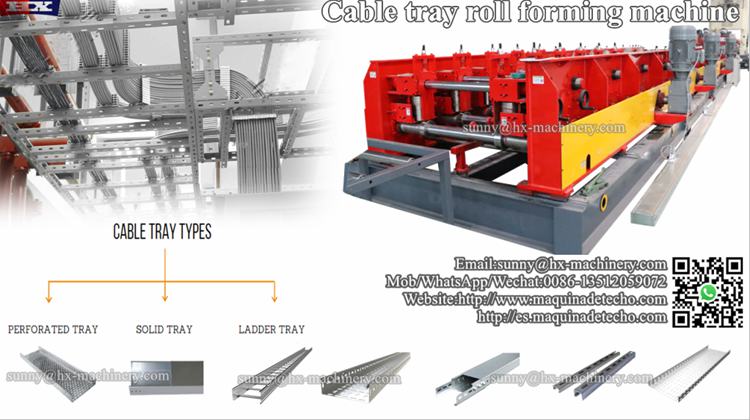

Cable tray making machines,cable tray roll forming machine,Cable Tray Production Line from TIANJIN HAIXING machinery factory make different sizes of cable tray, for example cable tray width from 100-600mm, height from 50-100mm. it is easy to change size by moving whole line rollers and cut blade positions.

Cable tray punching machine line

| Cable tray punching machineparameters | ||

| 1 | Equipment area | About 38×1.5×1.6m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 150-750 mm |

| 7 | Rolled strip thickness | 1.0(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Q235B cold rolled strip steel,hot rolled strip steel |

| 9 | Rolling workpiece length | 3000 mm |

| 10 | Online punching production speed | 6-8 m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 40KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±2mm |

Cable tray punching machine detailed images for reference

| 1 | 6T Uncoiler | 1. Maximum load-bearing capacity: 6T 2. Maximum roll width: 12-850mm 3. Inner diameter of roll: ф460-520 mm 4. Outer diameter of roll: ≤1600mm 5. Hydraulic tensioning, electric unwinding |

|

| 2 | Leveling servo feeding machine | 1.8 roller leveling 2. Leveling roller diameter: 90mm 3. Leveling motor: 4KW |

|

| 3 | 200 Ton punching machine | 200Tons Yangli press machine |  |

| 4 | Punching molds | Machine use the punching molds |  |

| 5 | High-speed platform | 1. Heavy-duty roller feed: 6 meters 2. Main motor power: 1.5KW 3. Electric opening and closing motor power: 0.37KW |

|

| 6 | Roll forming part | 1. Shaft diameter φ65mm 2. Shaft material 45# steel 3. Forming pass number 32 4. Main motor power 5.5KW×3 5. Automatic opening and closing motor 1.5KW×3 5. Roller material Cr12 6. Roller hardness HRC58-62 |

|

| 7 | Discharging platform | 1. 3m platform 2. Roller type 3. No power |

|

| 8 | Hydraulic station | Multiple solenoid valves Solenoid overflow valves Cooling system |

|

About cable tray production line did cable tray application :

A cable tray system is used to support insulated electrical cables used for power distribution, control, and communication. Cable trays are used as an alternative to open wiring or electrical conduit systems, and are commonly used for cable management in commercial and industrial construction.Besides such whole piece cable tray, we also have ladder type cable tray, or T shape cable tray

Cable tray production line have different shapes,for example :

A.Ladder Type Cable Tray

B.Solid Bottom Cable Tray

C.Trough Cable Tray

D.Channel Cable Tray

D.Wire Mesh Cable Tray

E.Single Rail Cable Tray

F.Perforated Cable Tray