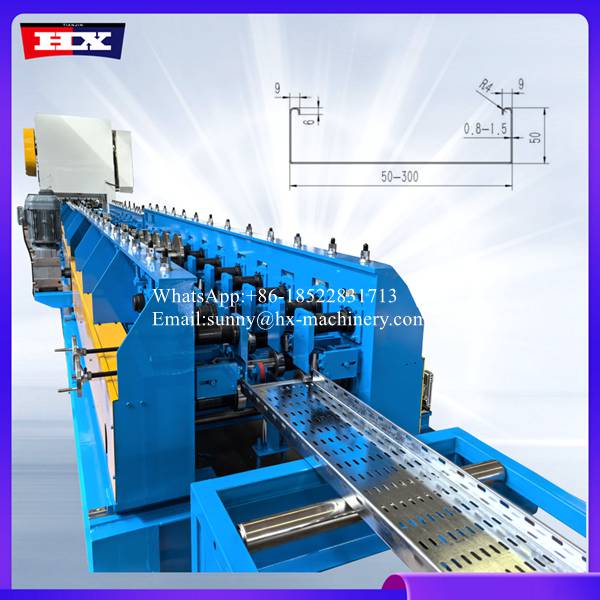

Cable tray roll former punching hole machine are reasonable.Cable tray forming machine belong to continuous roll forming: Through multiple passes (typically 10-20 or more) through forming rollers, coiled material (such as galvanized sheet or stainless steel) is gradually and continuously bent into the designed bridge cross-sectional shape (such as stepped, trough, or tray-shaped). This process is uninterrupted, with production speeds reaching 10-30 meters per minute, significantly improving production efficiency and reducing labor costs.

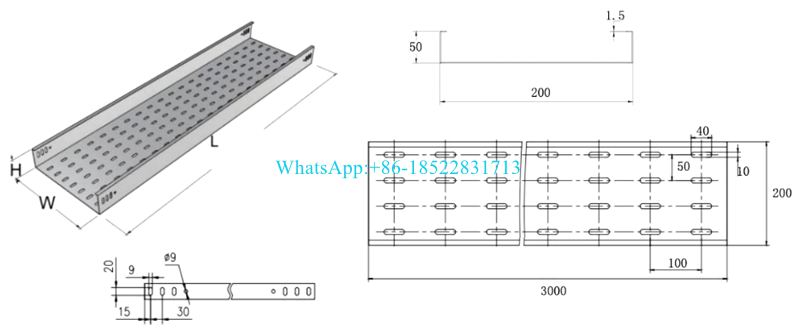

Cable Tray Drawing Model:Bottom:100-800 Waist high:50-200 technical details :

| Cable tray manufacturing machine price parameters | ||

|

||

| 1 | Equipment area | About 38×1.5×1.6m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 450-950 mm |

| 7 | Rolled strip thickness | 1.0(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Q235B cold rolled strip steel,hot rolled strip steel |

| 9 | Rolling workpiece length | 3000 mm |

| 10 | Online punching production speed | 6-8 m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 40KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±2mm |

Cable tray roll former punching hole machine detailed images

| A.6T Uncoiler Decoiler

1. Maximum load-bearing capacity: 6T

|

| B.Leveling servo feeding machine

1.8 roller leveling

|

| C.200 Ton punching machine :200 Ton punching machine with servo feeding

|

| D.High-speed platform

1. Heavy-duty roller feed: 6 meters

|

| E.Roll forming part

1. Shaft diameter φ65mm

|

| F.Discharging platform

1. 3m platform |

Cable tray punching machine price loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

About our service for cable tray forming machine

| Pre-sales consultation and customization | Provide equipment selection suggestions and production line configuration solutions based on your needs (such as bridge type, material, specifications, and output), and accept customized designs |

| Equipment installation and debugging | Professionals will come to install the equipment and conduct on-site debugging to ensure the normal operation of the equipment and the production of qualified products. |

| Technical training and operation | Provide training for your operation and maintenance personnel, including equipment operation, programming (such as touch screen settings), daily maintenance, simple troubleshooting, etc. |

| After-sales service and support | Provide warranty period (usually 1 year or as agreed), remote technical guidance, fault response, and regular return visits. |

| Repair and spare parts supply | Provide equipment maintenance services and supply original spare parts (such as rollers, dies, wearing parts, etc.) to ensure the service life and accuracy of the equipment. |