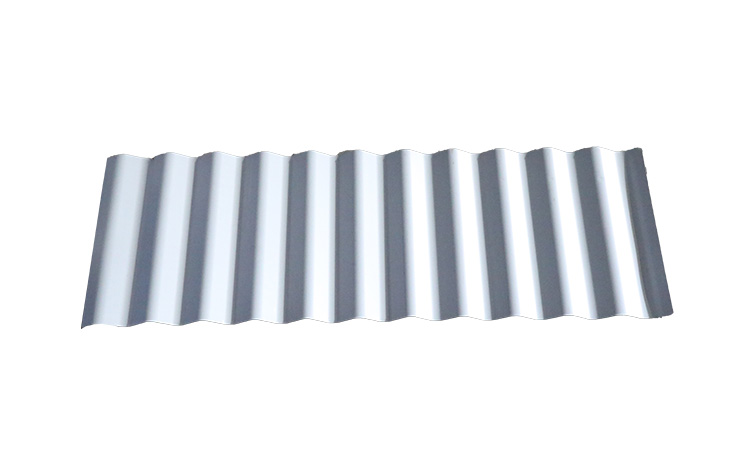

Corrugated Roll Machine is a robust, high-performance roll forming system designed for the efficient production of corrugated metal sheets. Widely used in construction, agriculture, and industrial applications, this machine transforms flat coil stock into durable, wave-shaped panels with superior strength and weather resistance.

| Parameters of Corrugated roll machine | |

|

|

| Weight of machine | 5800kg |

| Size of machine | 9500*1450*1900mm |

| Rollers | 24 rollers |

| Chain length | 1 inch |

| Feed Thickness | 0.18-0.4mm |

| Feed width | 900mm |

| Cutter | Cr12 |

| Shaft diameter | 70mm |

| Material of the wheel | 45# Steel Chrome-Plated |

| Main motor power | 7.5KW |

| Pump motor power | 4KW(with fan) |

| oltage | 440V, 50HZ, 3-phase electricity |

| Shear error | ±1.0mm |

| Cutting Method | Servo Cutting |

| Forming Speed | 10-15m/min |

Key Features & Benefits

Precision Roll Forming: Equipped with hardened, CNC-machined rollers that ensure consistent corrugation depth, pitch, and profile across every sheet. The multi-stage forming process gradually shapes the material without surface damage or distortion.

High-Speed Production: Advanced servo or AC motor drive systems deliver forming speeds of up to 40 meters per minute, enabling high-volume output with minimal cycle time.

Durable Construction: Heavy-duty welded frame and high-quality transmission components ensure long-term stability, reduced vibration, and minimal maintenance requirements.

Typical Applications:

Corrugated roofing sheets for industrial and residential buildings

Wall cladding and fencing panels

Agricultural barns and warehouse enclosures

Temporary structures and prefabricated houses

Ventilation ducting and decorative profiles

The loading and shipment :

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

About us:

Since 1996 year, HAIXING GROUP main products have evolved from a standard roll forming machine to a customized automated roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners.And we always adhering to the concept of “honesty is our aim, win win is our pursuit”, insisting on the service principles of “customer first, quality first, service first, after sales first”, efficiently and professionally complete the products required by customers.