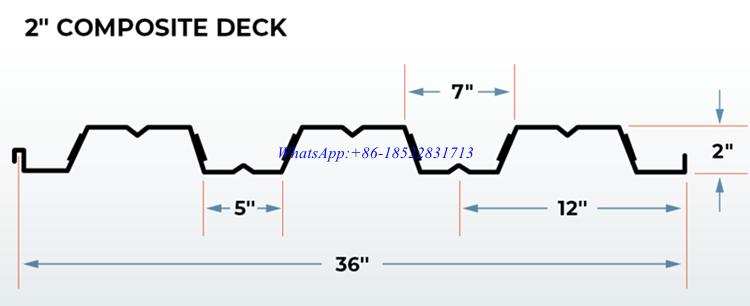

2” Composite floor deck roll forming machine production 2” composite deck is standard with an interlocking joint and a run-off leg so that the deck can be installed either with a button punched or a side lap fastener. Hanger tabs can be specified for drop ceiling attachment to the bottom of the deck.This kind floor decking machine with famours brand control box and motor .Raw materials thickness popular 22 ga.– 16 ga for composite floor deck.

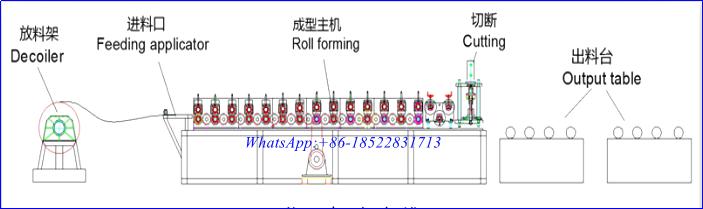

Full Automatic 2” Composite floor deck roll forming machine line main include :

1.Passive Decoiler

2.Feeding Platform with Pre-cutter

3.Roll Forming Mills

4.PLC Control System

5.Hydraulic Cutting System

6.Exit Rack for roofing production

3” Composite metal decking metal deck roll forming machine technical details :

| Model |  |

|

| No. | 2” Composite floor deck roll forming machine | |

| 1 | Suitable to process | Alu-zinc steel coil/Galvanized steel coil |

| 2 | Rollers | 26 rollers or according to final design |

| 3 | Dimensions | 14.5*1.8*2.0m |

| 4 | Motor Power | 15Kw*2 |

| 5 | Pump Station Motor | 4Kw,Lichao |

| 6 | Thickness of the plate | 0.8-1.5mm |

| 7 | Productivity | 10-15m/min |

| 8 | Material of the cutting blade | Cr12Mov,Quenched treatment 58℃-60℃ |

| 9 | Diameter of the roller | Φ90mm |

| 10 | Weight | About 12850kgs |

| 11 | Main structure of the machine | 450 H Beams |

| 12 | Processing precision | Within 1.0mm |

| 13 | Side panel of machine | 20mm |

| 14 | Chain Wheel and Cycle Chain | 2 Inch |

| 15 | Voltage | 380V 50Hz 3phases or as customer’s need |

| 16 | Control system | PLC control (Delta) |

| 17 | Frequency system | Delta |

| 18 | Drive mode | Gear driver |

| 19 | Touch screen | Delta |

| 20 | Rolling materials | 45# forging steel with chromium plate |

| 21 | Length Tolerance | ±2mm |

2” Composite floor deck roll forming machine line each part showing

Installation of metal decking metal deck roll forming machine

If installation is needed,the seller will dispatch a technician to the buyer’s factory abroad to assist regulating the machine.

The buyer should assist the seller to get the Chinese technician’s visa and should pay for the round trip air ticket ,local accommodation.and $150/day.

If installation is needed, the buyer shall make the following preparation before arrival of technicians.

A.Position the machine in the buyer’s factory.

B.Prepare necessary electric wiring.

C.Prepare material of trial running.

D.Provide labors for assistance and installation during installation