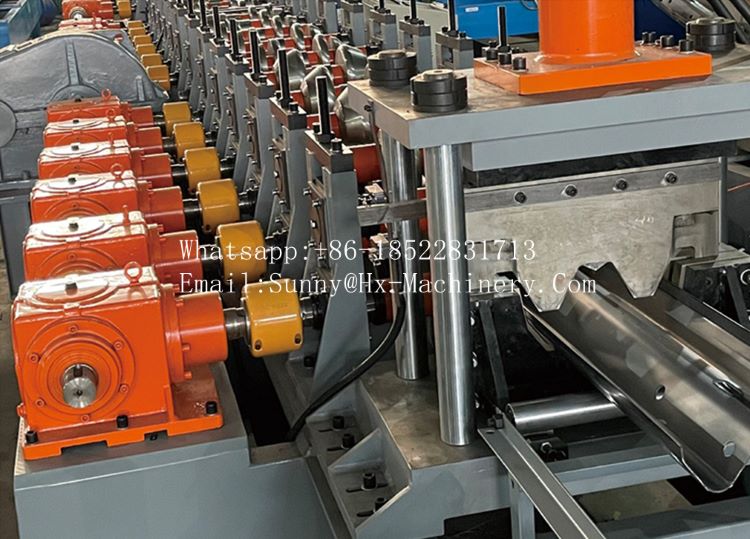

Guardrail Roll Forming Machine:The machine is perfect for efficient production of high-quality highway guardrails. It ensures precise, consistent forming with fast operation, making it ideal for large-scale manufacturing. The machine is easy to adjust for different designs and thicknesses, offering great flexibility. Built for durability, it provides reliable performance with low maintenance costs. A perfect solution for businesses looking to boost their guardrail production.

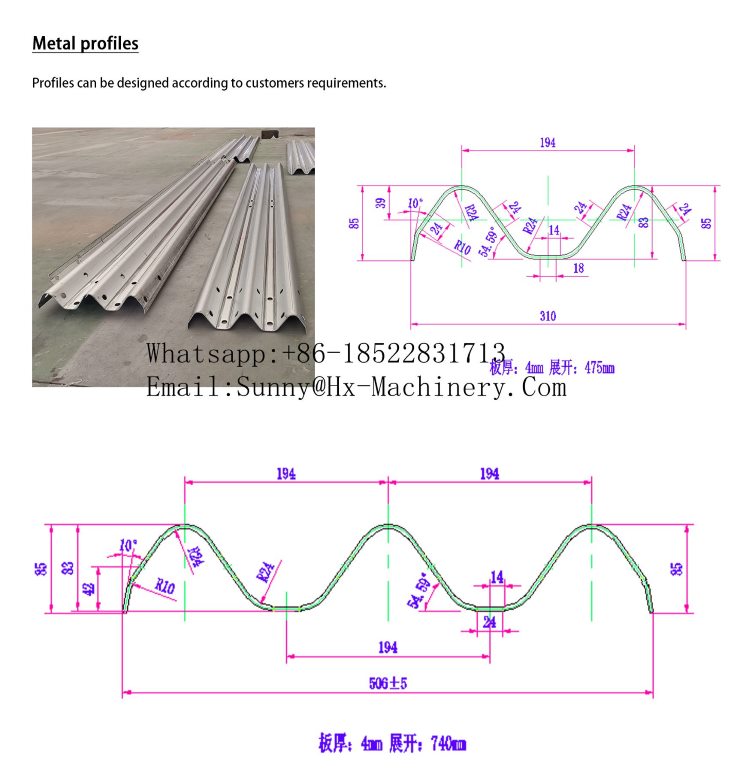

Our products can become in different sizes and we can customize with your need:

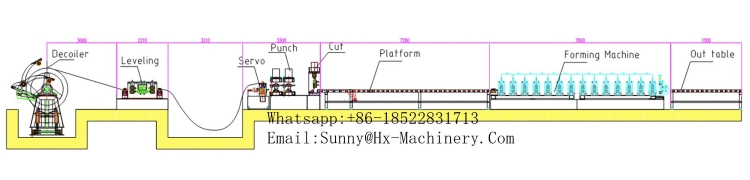

Production Process:

| Guardrail roll forming machine manufacturers parameters | ||

| 1 | Decoiler | 8 Ton single-arm decoiler |

| 2 | Machine body frame | 500H Beams welding |

| 3 | Forming guide feed frame | Side arch type |

| 4 | Forming Machine Type | 55 portal frame with chain drive |

| 5 | Diameter of shaft | Ø120 mm |

| 6 | Transmission System | TX230 distribution gearbox + 180 cross shaft universal coupling |

| 7 | Main Motor Power | Dual 22 kW motors with K107 reducer |

| 8 | Forming Speed | 5-15 m/min |

| 9 | Roller station | 15-18 rows |

| 10 | Material of rollers | High-quality CR12, quenched and precision machined |

| 11 | Hydraulic system power | 22 KW with four-valve plunger pump |

| 12 | Cutting Method | Hydraulic triple-blade shearing |

| 13 | Punching Units | Three sets (one for center hole, two for side holes) |

| 14 | Cutting blade | Cr12, Quenched treatment 58℃-62℃ |

| 15 | Forming Thickness | 2.0-4.0 mm ( Length Tolerance: ±2 mm) |

| 16 | Control System | Delta PLC, Doble 22 kW Delta inverters, Delta touch screen |

| 17 | Machine Dimensions | 1400mm*2400mm(L*W) |

And also our machine perfect for businesses looking to improve their guardrail production line, this roll forming machine delivers high-performance results with minimal effort. Whether you’re starting a new project or upgrading an existing one, this machine is an excellent choice.

Perforated guardrail roll forming machine loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

Advantages of using a guardrail roll forming machine include:

| High Precision | Ensures consistent, accurate guardrail profiles |

| Fast Production | Increases output with quick, automated processes |

| Durable | Built to last with strong, high-quality components |

| Energy-Efficient | Low power consumption reduces operational costs. |

| Versatile | Can produce different guardrail shapes and sizes |

| Customizable | Adjustable settings to meet specific design requirements |