Guardrail roll forming machine manufacturers specialize in producing advanced machines that efficiently create high-quality road guardrails. These machines use cold-rolling technology to transform raw materials like steel into precise guardrail profiles, ensuring durability and safety. Designed for high-speed production, they offer flexibility for various types of guardrails, such as W-beam and Thrie-beam models. Manufacturers provide custom solutions tailored to specific needs, combining innovation, productivity, and high industry standards to ensure both safety and environmental compliance.

Advantages of Guardrail Roll Forming Machine Manufacturers:

Guardrail roll forming machine manufacturers offer several key advantages: they provide high-speed, efficient production of durable and precise guardrails; ensure cost-effectiveness by minimizing material waste; and offer customizable solutions for different road safety needs. These machines are easy to operate, require minimal maintenance, and produce consistent quality, making them essential for large-scale infrastructure projects and road safety applications.

Application in different scenarios:

Guardrail roll forming machines are essential in producing road safety barriers for highways, bridges, and urban roads. They are used to manufacture various types of guardrails, such as W-beam and Thrie-beam, quickly and efficiently. These machines ensure high-speed, cost-effective production while maintaining precision, making them crucial for large-scale infrastructure projects and custom road safety solutions.

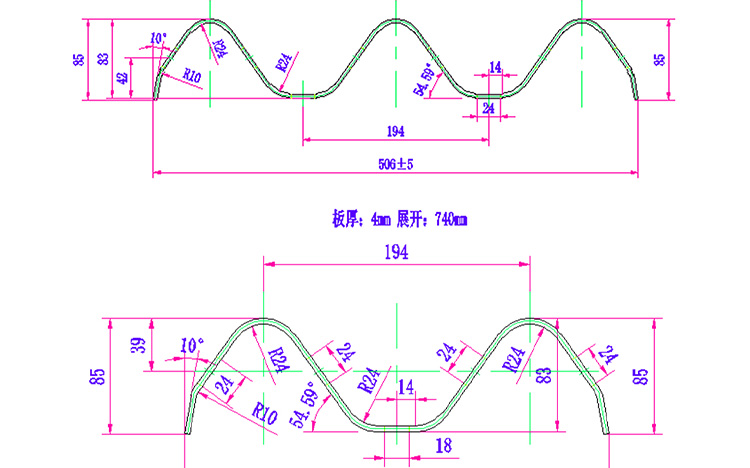

The size of our product(can customized with your need):

| guardrail roll forming machine manufacturers parameters | ||

| 1 | Decoiler | 8 Ton single-arm decoiler |

| 2 | Machine body frame | 500H Beams welding |

| 3 | Forming guide feed frame | Side arch type |

| 4 | Forming Machine Type | 55 portal frame with chain drive |

| 5 | Diameter of shaft | Ø120 mm |

| 6 | Transmission System | TX230 distribution gearbox + 180 cross shaft universal coupling |

| 7 | Main Motor Power | Dual 22 kW motors with K107 reducer |

| 8 | Forming Speed | 5-15 m/min |

| 9 | Roller station | 15-18 rows |

| 10 | Material of rollers | High-quality CR12, quenched and precision machined |

| 11 | Hydraulic system power | 22 KW with four-valve plunger pump |

| 12 | Cutting Method | Hydraulic triple-blade shearing |

| 13 | Punching Units | Three sets (one for center hole, two for side holes) |

| 14 | Cutting blade | Cr12, Quenched treatment 58℃-62℃ |

| 15 | Forming Thickness | 2.0-4.0 mm ( Length Tolerance: ±2 mm) |

| 16 | Control System | Delta PLC, Doble 22 kW Delta inverters, Delta touch screen |

| 17 | Machine Dimensions | 1400mm*2400mm(L*W) |

In general, the guardrail roll forming machine manufacturers is an indispensable piece of equipment in modern road construction. Providing efficient, precise, and safe solutions for the construction of highways, urban roads, and other transportation infrastructure. With advancements in technology, the performance of guardrail machines continues to improve. And they will play an increasingly important role in future road safety projects.

Those photos about product process:

| A.Decoiler

Bearing weight: 8t

|

| B.Feeding

|

| C.Punching

With Three sets (one for center hole, two for side holes)

|

| D.Forming

1.The speed:5-15m/min 2.The thickness:2.0mm-4.0mm

|

| E.Cutting

1.The blade:Cr12, Quenched treatment 58℃-62℃ 2.The method:Hydraulic triple-blade shearing

|

| F.Discharge

|

Perforated guardrail roll forming machine manufacturers loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |