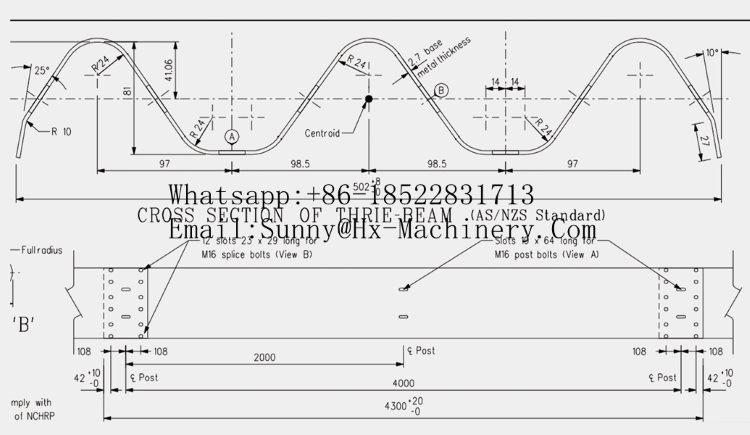

As Guardrail roll forming machine suppliers provide specialized equipment used in the production of road safety barriers, such as guardrails for highways, bridges, and urban roads. These suppliers offer a variety of machines designed to efficiently manufacture different types of guardrails, including W-beam, Thrie-beam, and other custom profiles. They build their machines for precision, producing each guardrail with exact specifications to ensure durability and safety.

We supply reliable and high-performance roll forming machines and export all kinds of machines and also provid worry-free after-sales service for you. Exporting to more than 80 countries around the world, and having sufficient experience.

The size of our product(can customized with your need):

| Guardrail roll forming machine suppliers parameters | ||

| 1 | Decoiler | 8 Ton single-arm decoiler |

| 2 | Machine body frame | 500H Beams welding |

| 3 | Forming guide feed frame | Side arch type |

| 4 | Forming Machine Type | 55 portal frame with chain drive |

| 5 | Diameter of shaft | Ø120 mm |

| 6 | Transmission System | TX230 distribution gearbox + 180 cross shaft universal coupling |

| 7 | Main Motor Power | Dual 22 kW motors with K107 reducer |

| 8 | Forming Speed | 5-15 m/min |

| 9 | Roller station | 15-18 rows |

| 10 | Material of rollers | High-quality CR12, quenched and precision machined |

| 11 | Hydraulic system power | 22 KW with four-valve plunger pump |

| 12 | Cutting Method | Hydraulic triple-blade shearing |

| 13 | Punching Units | Three sets (one for center hole, two for side holes) |

| 14 | Cutting blade | Cr12, Quenched treatment 58℃-62℃ |

| 15 | Forming Thickness | 2.0-4.0 mm ( Length Tolerance: ±2 mm) |

| 16 | Control System | Delta PLC, Doble 22 kW Delta inverters, Delta touch screen |

| 17 | Machine Dimensions | 1400mm*2400mm(L*W) |

Our Guardrail Roll Forming Machines offer precise and efficient solutions for producing road safety barriers. Designed for highways, bridges, and urban roads, these machines create various guardrail profiles like W-beam and Thrie-beam. As trusted suppliers, we provide custom solutions to meet your specific needs, along with full support to ensure smooth operation. Our machines ensure reliability and help you deliver top-quality road safety infrastructure with consistent results.

Perforated Guardrail roll forming machine loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

With our customer: