Multiwave Glazed Roll Froming Machine represents the pinnacle of innovation in modern metal profiling technology. Engineered for the high-volume production of premium glazed building panels, this advanced system seamlessly integrates precision forming, automated glazing application, and intelligent control to deliver superior product quality and operational efficiency.

| Parameters of Multiwave Glazed Roll Froming Machine | |

|

|

| Weight of machine | 5820kg |

| Size of machine | 7100*1900*2000mm |

| Rollers | 13 rollers |

| Chain length | 1 inch |

| Feed Thickness | 0.3-0.8mm |

| Feed width | 1250mm |

| Cutter | Cr12 |

| Shaft diameter | 70mm |

| Material of the wheel | 45# Steel Chrome-Plated |

| Main motor power | 5.5KW |

| Pump motor power | 5.5KW(with fan) |

| oltage | 380V, 50HZ, 3-phase electricity |

| Shear error | ±1.0mm |

| Cutting Method | Servo Cutting |

| Forming Speed | 4-6m/min |

Strength of our Multiwave Glazed Roll Froming Machine:

Patented Multiwave Roll Forming System: Utilizing a custom-designed, multi-stage forming process with CNC-machined rollers, the machine ensures exceptionally accurate and consistent wave profiles for every panel. This results in perfect alignment, enhanced structural integrity, and a flawless aesthetic finish.

Superior Efficiency & Durability: Constructed from high-grade components and featuring a robust welded frame, the machine guarantees long-term stability and minimal maintenance. High-speed synchronized drives and automated cutting optimize production rates, significantly reducing waste and labor costs.

Ideal for manufacturing:

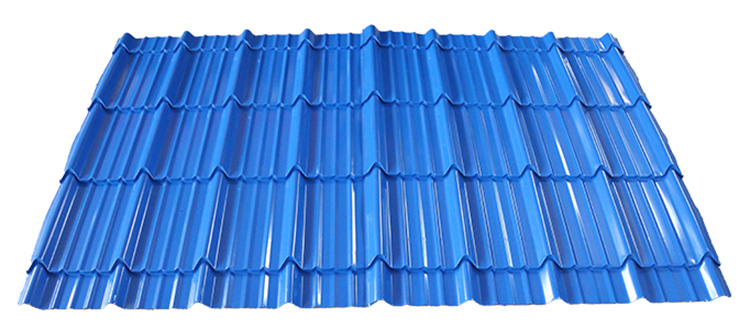

Glazed Roofing & Wall Cladding Panels for industrial, commercial, and agricultural buildings.

Architectural Composite Panels with integrated insulation.

Specialty Corrugated Sheets for solar farms, facades, and interior design.

The loading and shipment :

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

About us:

Since 1996 year, HAIXING GROUP main products have evolved from a standard roll forming machine to a customized automated roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners.

Main machine includes roof roll forming machine, light keel roll forming machine, cable tray roll forming machine, strut channel roll forming machine, rack roll forming machine, floor deck roll forming machine, purlin machine, leveling and slitting machine, metal fence roll forming machine, gutter roll forming machine, downspout roll forming machine, door frame machine, shutter door roll forming machine, highway guardrail roll forming machine, and other related construction equipment.