Perforated cable tray machine is commonly used to make all kinds of cable trays, which is widely used in electrical fields, decorations, industrial constructions etc. According to the final cable products, it can be conveniently divided into three types: Non-hole trough cable tray, cable ladder, and perforated channel cable tray. This kind cable tray forming machine could produce all these different types of cable trays with different raw materials like: hot-dip galvanized steel, pre-galvanized steel, hot-rolled and cold-rolled steel, stainless steel and aluminum.

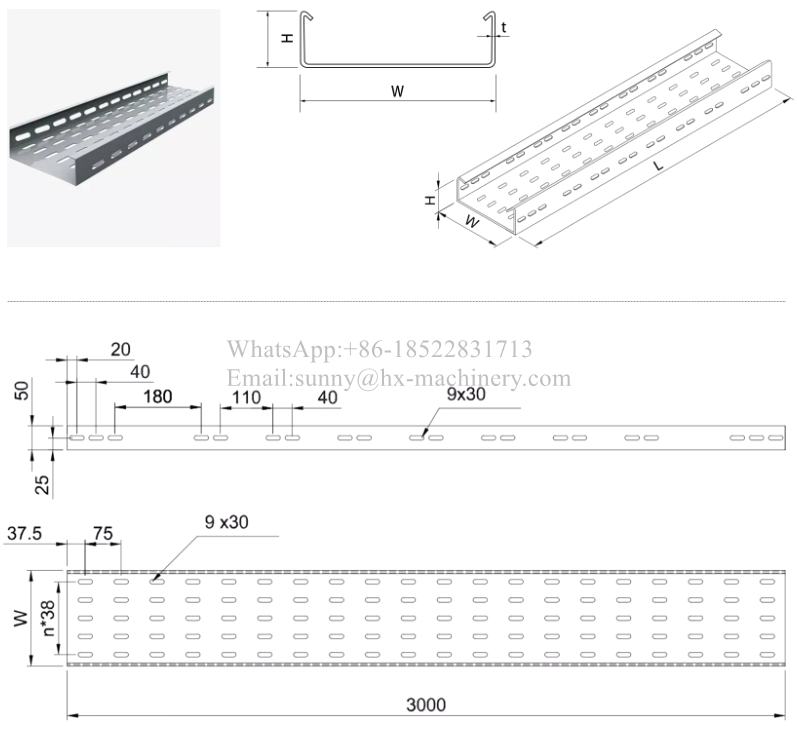

Perforated cable tray machine Drawing Model:Bottom:100-450 Waist high:50-200 technical details :

| Cable tray roll forming machine parameters | ||

|

||

| 1 | Equipment area | About 36×1.5×1.6m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 150-650 mm |

| 7 | Rolled strip thickness | 1.0(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Q235B cold rolled strip steel,hot rolled strip steel |

| 9 | Rolling workpiece length | 3000 mm |

| 10 | Online punching production speed | 6-8 m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 38KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±2mm |

Perforated cable tray machine manufacturers photos for reference

Perforated cable tray roll forming machine loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

Why choose us?

| 1 | Complete after-sales service and technical support |

| 2 | Excellent performance and high-precision processing |

| 3 | High flexibility and versatility |

| 4 | Excellent reliability and durability |