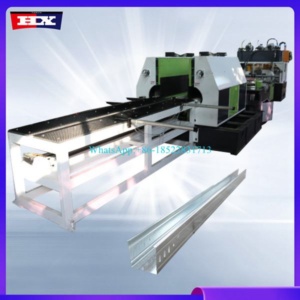

Perforated cable tray roll forming machine is an automated production line for metal processing. Its core working principle is to continuously feed metal coils (usually steel or aluminum strips) into a series of pairs of customized forming rollers. Each pair of rollers performs small, progressive bending on the metal, ultimately processing the straight metal strip continuously and at high speed into the desired specific cross-sectional shape (in this case, the cross-section of a perforated cable tray).

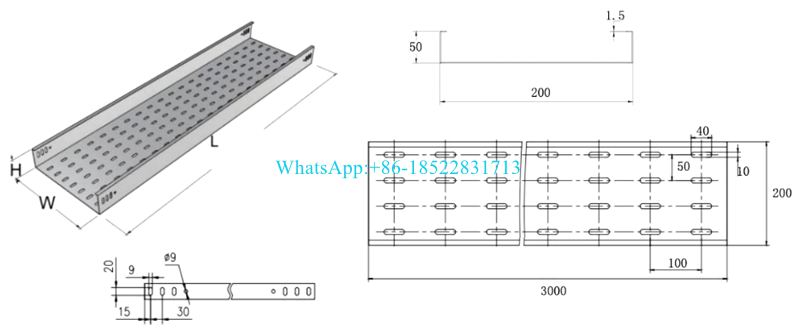

Cable Tray Drawing Model:Bottom:100-800 Waist high:50-200 technical details :

| Perforated cable tray roll forming machine parameters | ||

|

||

| 1 | Equipment area | About 38×1.5×1.6m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 450-950 mm |

| 7 | Rolled strip thickness | 1.0(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Q235B cold rolled strip steel,hot rolled strip steel |

| 9 | Rolling workpiece length | 3000 mm |

| 10 | Online punching production speed | 6-8 m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 40KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±2mm |

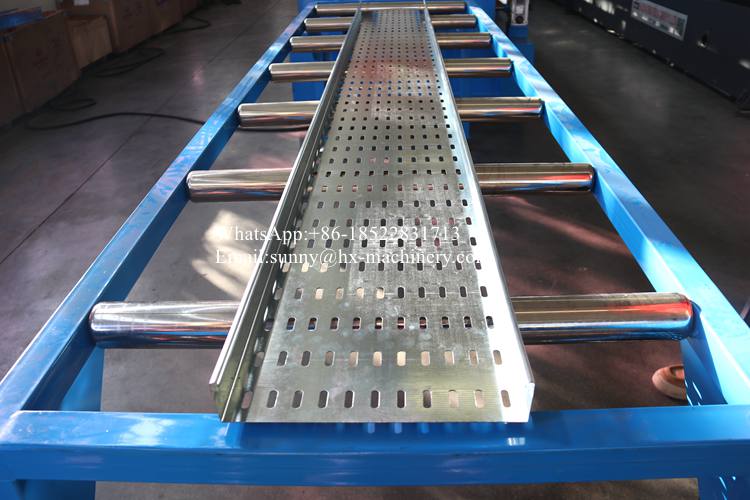

Cable tray production line detailed images

| A.6T Uncoiler Decoiler

1. Maximum load-bearing capacity: 6T

|

| B.Leveling servo feeding machine

1.8 roller leveling

|

| C.200 Ton punching machine :200 Ton punching machine with servo feeding

|

| D.High-speed platform

1. Heavy-duty roller feed: 6 meters

|

| E.Roll forming part

1. Shaft diameter φ65mm

|

| F.Discharging platform

1. 3m platform

|

Perforated cable tray roll forming machine loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

About our service for galvanized cable tray making machine

| Pre-sales consultation and customization | Provide equipment selection suggestions and production line configuration solutions based on your needs (such as bridge type, material, specifications, and output), and accept customized designs |

| Equipment installation and debugging | Professionals will come to install the equipment and conduct on-site debugging to ensure the normal operation of the equipment and the production of qualified products. |

| Technical training and operation | Provide training for your operation and maintenance personnel, including equipment operation, programming (such as touch screen settings), daily maintenance, simple troubleshooting, etc. |

| After-sales service and support | Provide warranty period (usually 1 year or as agreed), remote technical guidance, fault response, and regular return visits. |

| Repair and spare parts supply | Provide equipment maintenance services and supply original spare parts (such as rollers, dies, wearing parts, etc.) to ensure the service life and accuracy of the equipment. |