Rack shelf roll forming machine with high-speed production enables continuous manufacturing at speeds of 15-50 meters per minute, vastly outperforming single-press or manual fabrication.

Rack Shelf Roll Forming Machine is an integrated flexible manufacturing system for producing cold-formed, corrugated decking panels.It translates the structural principles of sheet metal stiffening through geometry into a rapid, repeatable industrial process. Its output is a critical, safety-rated component in material handling and storage infrastructure, where performance, consistency, and cost-effectiveness are paramount.This machine is a cornerstone asset for manufacturers serving the global logistics, warehousing, and retail sectors.

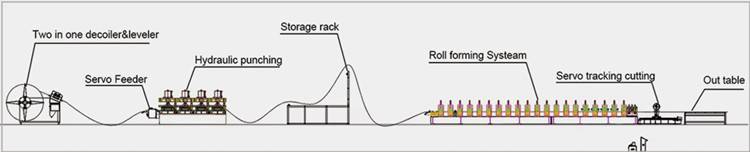

Rack shelf roll forming machine working flow

Uncoiling → Leveling → Roll forming system→ Punching system→ Cutting system → Products receiving table

| Rack shelf roll forming machine main parameters | |

| Forming Rollers | 19rollers |

| Roller Material | Cr12 mold steel, vacuum quenching treatment, hardness HRC58–62 |

| Main Shaft Diameter | Finished diameter Ø90 mm |

| Main Shaft Material | 45# steel with quenching and tempering treatment |

| Motor Power | 11 kW *2 motors, K97 series hard-tooth gearbox |

| Transmission | Gearbox drive, coupled with universal couplings |

| Machine Frame | Cast iron archway 48 |

| Servo Punching | Non-stop servo punching,dual-module reverse punching |

| Cutting Method | Flying tracking saw cutting (with scrap) |

| Discharge Table | 3 m × 2 Pieces, roller-type support |

| Forming Thickness | 1.5-2.5mm |

| Forming Speed | 10-15m/min |

| Inverter | Delta brand |

| LCD Screen | Display Control Electric |

| Low-Voltage Electrical Components | Delixi or Chint |

| Hydraulic System | 5.5Kw |

| Bearings | Harbin Bearings |

| Reducer | Ruibofeng Reducer Co., Ltd. |

| Decoiler | Motorized decoiler with hydraulic expanding mandrel, load capacity 5 tons Inner diameter: 480–520 mm Max. outer diameter: 1600 mm |

| Leveling Section | 1.5 rollers 2. Leveling shaft diameter 70 mm 3. Material 40Cr high frequency quenching |

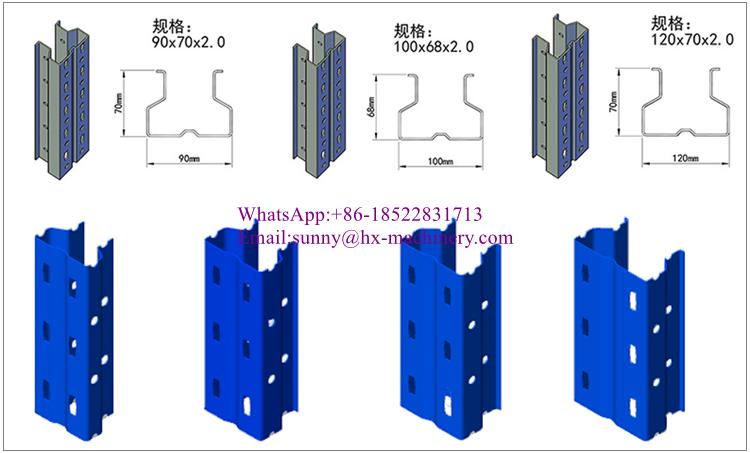

Steel upright pallet rack roll forming machine each part photos showing

Storage rack roll forming making machinery package and loading

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | TAll spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |