Rack upright roll forming machine is the core industrial equipment that enables the efficient, precise, and cost-effective mass production of the standardized, high-strength vertical uprights essential for modern warehouse storage and logistics infrastructure.Its output is characterized by structural integrity, dimensional accuracy, and interoperability within racking systems.

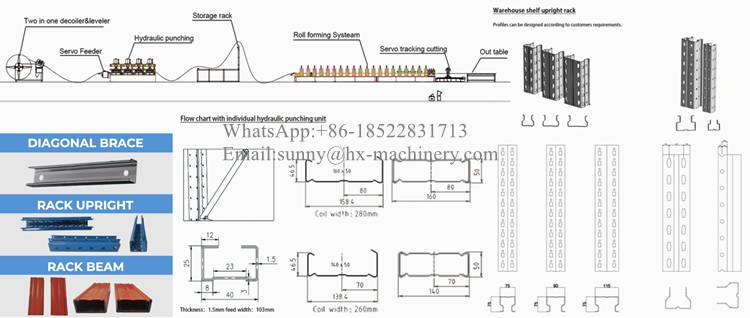

Rack upright roll forming machine working flow

Uncoiling → Leveling → Roll forming system→ Punching system→ Cutting system → Products receiving table

| Upright rack roll forming machinemain parameters | |

| Forming Rollers | 19rollers |

| Roller Material | Cr12 mold steel, vacuum quenching treatment, hardness HRC58–62 |

| Main Shaft Diameter | Finished diameter Ø90 mm |

| Main Shaft Material | 45# steel with quenching and tempering treatment |

| Motor Power | 11 kW *2 motors, K97 series hard-tooth gearbox |

| Transmission | Gearbox drive, coupled with universal couplings |

| Machine Frame | Cast iron archway 48 |

| Servo Punching | Non-stop servo punching,dual-module reverse punching |

| Cutting Method | Flying tracking saw cutting (with scrap) |

| Discharge Table | 3 m × 2 Pieces, roller-type support |

| Forming Thickness | 1.5-2.5mm |

| Forming Speed | 10-15m/min |

| Inverter | Delta brand |

| LCD Screen | Display Control Electric |

| Low-Voltage Electrical Components | Delixi or Chint |

| Hydraulic System | 5.5Kw |

| Bearings | Harbin Bearings |

| Reducer | Ruibofeng Reducer Co., Ltd. |

| Decoiler | Motorized decoiler with hydraulic expanding mandrel, load capacity 5 tons Inner diameter: 480–520 mm Max. outer diameter: 1600 mm |

| Leveling Section | 1.5 rollers 2. Leveling shaft diameter 70 mm 3. Material 40Cr high frequency quenching |

Upright rack roll forming machine each part photos showing

Specialized & Emerging Applications For shelf storage rack cold roll forming machine

| Shelf Panels | This equipment produces shelf panels for supermarkets, warehouses, and other similar applications. It can process shelves of varying widths. |

| Uprights/Posts | The vertical support columns for manufacturing shelving are typically punched in-line to allow for later height adjustments. |

| Rack Beams | Produces main load-bearing components for connecting columns, load-bearing shelves, or pallets. |

| Pallet Racking | This type of racking is used to manufacture pallet-bearing racks, drive-in racks, and similar systems. These racks have high load-bearing capacity and high storage density. |

| Tool Racks | Specialized storage equipment for manufacturing heavy molds that can withstand hundreds of kilograms to several tons. |