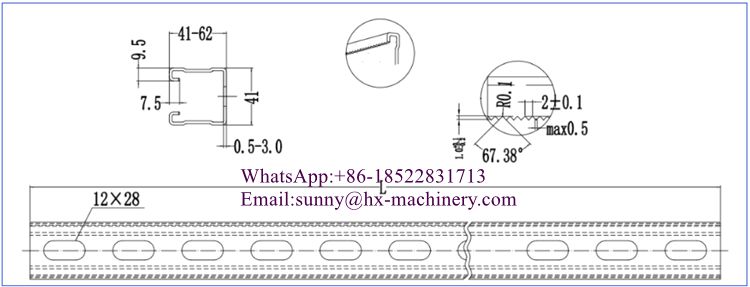

Roll forming machine for solar structure is a highly specialized piece of industrial equipment designed for the continuous, The machine line is engineered to produce high-strength photovoltaic mounting channels with exceptional precision and efficiency. Designed for structural profiles such as 41×41, 41×52, 41×62, and 41×72, this machine ensures stable shaping accuracy and superior product durability for solar support systems.

◊ High Efficiency & Output: Enables mass production to meet large-scale project demands.

◊ Consistent Quality: Produces uniform profiles with precise dimensions.

◊ Material & Cost Savings: Minimizes waste compared to traditional fabrication methods.

◊ Flexibility: Can be configured to produce various profiles by changing the roll forming stations.

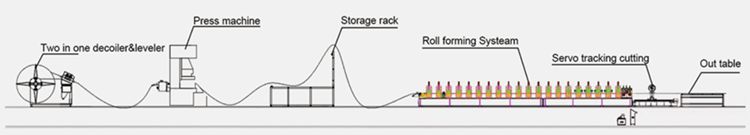

Punch press process flow:

Punching process: Unloading — feeding — forming — punching — cutting — discharging

This strut channel roll forming machine line can roll steel products with a maximum thickness of 2.0mm, and can produce steel products with size 41*21/41*41mm/41*52mm,thickness range 1.5(±0.03)~2.5(±0.03) mm

| Roll forming machine for solar panel structure parameters | |

| Forming Rollers: | 26 Rollers |

| Roller Material: | Cr12 mold steel, vacuum quenching treatment, hardness HRC58–62 |

| Main Shaft Diameter: | Finished diameter Ø80 mm |

| Main Shaft Material: | 45# steel with quenching and tempering treatment |

| Motor Power: | 18.5 kW *2 motors, K97 series hard-tooth gearbox |

| Transmission: | Gearbox drive, coupled with universal couplings |

| Machine Frame: | Cast iron archway 48 |

| Servo Punching | Non-stop servo punching, dual-module reverse punching |

| Cutting Method | Flying tracking saw cutting (with scrap) |

| Discharge Table | 3 m × 2 Pieces, roller-type support |

| Forming Thickness | 1.5 – 2.5 mm |

| Forming Speed | 10-15 m/min |

| Inverter | INVT brand |

| LCD Screen | Display Control Electric |

| Low-Voltage Electrical Components | Delixi or Chint |

| Hydraulic System | 11 kW × 2 pump station (for punching) 4 kW pump station (for cutting) 3 kW pump station (for pressing) |

| Bearings | Harbin Bearings |

| Reducer | Ruibofeng Reducer Co., Ltd. |

| Decoiler | Motorized decoiler with hydraulic expanding mandrel, load capacity 5 tons Inner diameter: 480–520 mm Max. outer diameter: 1600 mm |

| Leveling Section | 5 rollers, leveling shaft diameter 70 mm |

Roll forming machine for solar structure photos showing

Solar mounting roll forming machine loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

Why choose us?

| 1 | Complete after-sales service and technical support |

| 2 | Excellent performance and high-precision processing |

| 3 | High flexibility and versatility |

| 4 | Excellent reliability and durability |