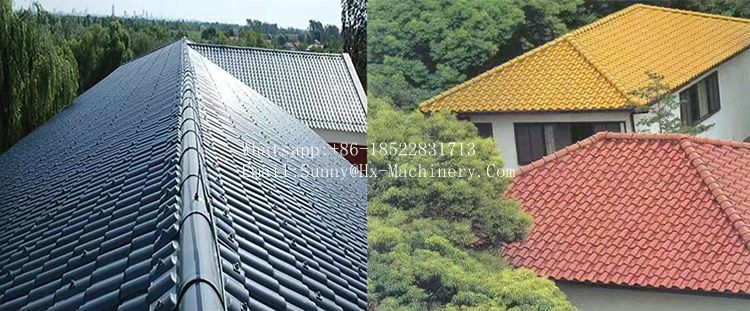

Roof Tile Roll Forming Machine is designed to efficiently produce roofing tiles with excellent accuracy and smooth finishes. It transforms raw metal sheets, such as steel and aluminum, into aesthetically pleasing, durable roof tiles for residential, commercial, and industrial buildings. This machine is highly automated, ensuring fast production cycles with minimal human intervention.

| Parameters of roof tile roll forming machine | |

|

|

| Weight of machine | 5800kg |

| Size of machine | 7000*1900*2000mm |

| Rollers | 15 rollers |

| Chain length | 1 inch |

| Feed Thickness | 0.3-0.8mm |

| Feed width | 1200 |

| Cutter | Cr12 |

| Shaft diameter | 70mm |

| Material of the wheel | 45# Steel Chrome-Plated |

| Main motor power | 5.5KW |

| Pump motor power | 5.5KW(with fan) |

| Voltage | 380V, 50HZ, 3-phase electricity |

| Shear error | ±1.0mm |

| Cutting Method | Servo Cutting |

| Forming speed | 4-6m/min |

To get a favorable price and more machines of our machine factory!

Features:

Our control system is user-friendly and highly intelligent, with customizable language options to suit your needs.

The machine offers quick setup adjustments, minimizing downtime and optimizing production efficiency.

Capable of producing various roofing tile profiles to meet specific project needs.

Applications:

The Roof Tile Roll Forming Machine is ideal for producing roofing tiles used in homes, commercial buildings, factories, and warehouses. It’s especially popular in regions where aesthetic appeal and weather resistance are top priorities. The machine can produce tiles in various sizes and designs, making it a preferred choice for both new constructions and renovations.

We Provide Service:

Our roof tile roll forming machine is designed to provide efficient and reliable performance for your production needs. We offer technical support and services to ensure that your machine operates at its optimal capacity.

Our technical support team is available to assist you with any questions or concerns you may have about the installation, operation, and maintenance of the machine. We can also provide troubleshooting services to help you identify and resolve any issues that may arise.

In addition to technical support, we offer a range of services to help you maximize the productivity of your roof tile roll forming machine. These services include training and education programs to help your team use the machine effectively, as well as maintenance and repair services to keep your machine in top condition.

We offer worldwide shipping for our machine. The shipping cost and delivery time depend on the destination country. They also vary based on the transportation method chosen by the customer. We will provide all necessary documents and information to ensure a smooth and hassle-free delivery process.