Shelf Rack Roll Forming Machine

A shelf rack roll forming machine is a specialized production line designed to continuously manufacture the main structural components for light-to-medium-duty storage shelving systems. Using a cold-forming process, it shapes steel coils into various standardized profiles.In short, this machine automates the efficient manufacturing of the complete metal framework for modular storage shelving systems.

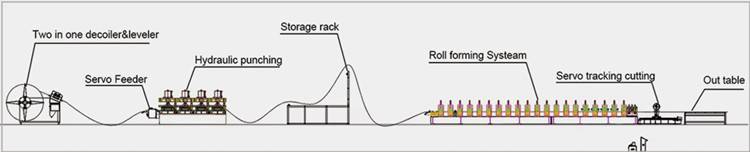

Shelf rack roll forming machine working flow

Uncoiling → Leveling → Roll forming system→ Punching system→ Cutting system → Products receiving table

| Upright roll forming machinemain parameters | |

| Forming Rollers | 19rollers |

| Roller Material | Cr12 mold steel, vacuum quenching treatment, hardness HRC58–62 |

| Main Shaft Diameter | Finished diameter Ø90 mm |

| Main Shaft Material | 45# steel with quenching and tempering treatment |

| Motor Power | 11 kW *2 motors, K97 series hard-tooth gearbox |

| Transmission | Gearbox drive, coupled with universal couplings |

| Machine Frame | Cast iron archway 48 |

| Servo Punching | Non-stop servo punching,dual-module reverse punching |

| Cutting Method | Flying tracking saw cutting (with scrap) |

| Discharge Table | 3 m × 2 Pieces, roller-type support |

| Forming Thickness | 1.5-2.5mm |

| Forming Speed | 10-15m/min |

| Inverter | Delta brand |

| LCD Screen | Display Control Electric |

| Low-Voltage Electrical Components | Delixi or Chint |

| Hydraulic System | 5.5Kw |

| Bearings | Harbin Bearings |

| Reducer | Ruibofeng Reducer Co., Ltd. |

| Decoiler | Motorized decoiler with hydraulic expanding mandrel, load capacity 5 tons Inner diameter: 480–520 mm Max. outer diameter: 1600 mm |

| Leveling Section | 1.5 rollers 2. Leveling shaft diameter 70 mm 3. Material 40Cr high frequency quenching |

Rack upright roll forming machine each part photos showing

The storage rack roll forming machine features

| Process | Uncoils, punches (for connector holes), incrementally forms via tandem rollers, and cuts to length. |

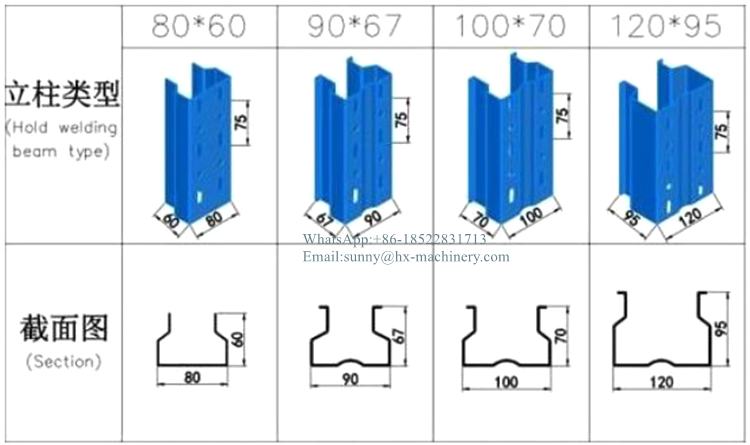

| Output | Produces upright frames (with standardized teardrop or keyhole slots) and beams (with welded end connectors) for pallet racking systems. |

| Advantages | High-speed production, consistent quality, material efficiency, and the ability to produce various profiles with quick tooling changeovers. |

| Application | Essential for manufacturing selective, drive-in, and cantilever racking systems used in logistics and industrial storage. |