Slitting line is a critical machine in metal processing that cuts a wide master coil of metal (steel, aluminum, stainless steel, etc.) longitudinally into multiple narrower strips of precise widths.

Slitting line is designed for high-efficiency metal processing. It provides precise slitting and cutting of coils into narrow strips with consistent quality. The machine offers quick setup, easy operation, and minimal downtime. It can handle various materials, including steel, aluminum, and stainless steel. With advanced technology, the slitting line ensures smooth operation and reduces the risk of defects. It is ideal for industries such as automotive, construction, and manufacturing. Whether you need to process thin or thick coils, our slitting line delivers reliable performance every time.

| Main parameters of slitting line | |

| Raw materials grade | Galvanized steel coil/Cold rolled coil/Color coil |

| Raw materials thickness | 0.3~3.0mm |

| Raw materials width | 1250mm |

| Raw materials inner diameter | Φ508mm/610mm |

| Raw materials outer diameter | ≤Φ1500mm |

| Raw materials coil weight | 5Tons |

| Slitting speed | 0~25m/min(During normal work) |

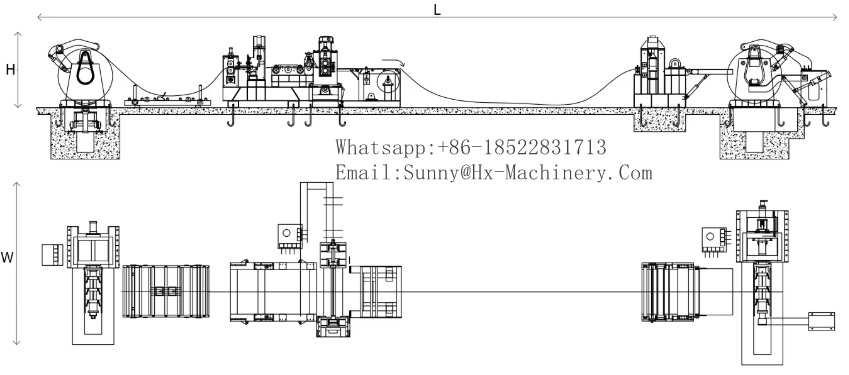

| Land occupation area | About 35m×5m |

This line mainly includes: hydraulic uncoiler, slitter and cutter, conveyor, hydraulic recoiler, or with roll forming machine,etc.

Some parts of the machine:

| A.Decoiler

Single cantilever structure bearing capacity 5Tons Support range:470-530mm hydraulic tension electric unwinding power:5.5KW frequency conversion and main motor 5.5KW Hydraulic pump 4KW

|

| B.Leveling

Hydraulic shovel head with two shaftsand total 11rollers(Up 5rows ,down 6rows ) roller diameter 90mm

|

| C.Slitting

slitting roll diameter 140mm-160mm Blade tool outer diameter 240-260mm Main motor power :7.5KW

|

| D.Damping

Double cylinder diameter 80mm Main frame use 10 mm thick iron plate welding Upper and Down iron plates with a thickness of 14 mm

|

| D.Collect waste

Power 2.7Kw*1set

|

| E. Hydraulic re-decoiler with coil car

|

About Our Company – TIANJIN HAIXING

Tianjin Haixing is a professional manufacturer of cold roll forming machines.Our main products include roof roll forming machines, light keel roll forming machines, floor deck roll forming machines, purlin machines, leveling and slitting machines, metal fence roll forming machines, gutter roll forming machines, downspout roll forming machines, door frame machines, shutter door roll forming machines, highway guardrail roll forming machines, and other construction equipment.

We have extensive experience meeting the needs of different countries.This includes profile drawing, operation languages, thickness range, instruction manuals, installation, and after-sales online support. Our equipment features medium to high configurations, including top-brand PLCs, motors, frequency converters, long service life, remote control, multifunctionality, and energy-saving capabilities.

Click to get more information about our machine and a more favorable price!