slitting machine steel cuts steel coils into precise strips. It operates quickly with high accuracy. Adjustable slitting widths cater to various production needs. The machine reduces material waste during high-speed operations. It is easy to operate and maintain. Designed for durability, it ensures long-term performance. Ideal for industries like steel manufacturing and metal processing. The machine improves overall production efficiency.

| Main parameters of slitting machine steel | |

| Raw materials grade | Galvanized steel coil/Cold rolled coil/Color coil |

| Raw materials thickness | 0.3~3.0mm |

| Raw materials width | 1250mm |

| Raw materials inner diameter | Φ508mm/610mm |

| Raw materials outer diameter | ≤Φ1500mm |

| Raw materials coil weight | 5Tons |

| Slitting speed | 0~25m/min(During normal work) |

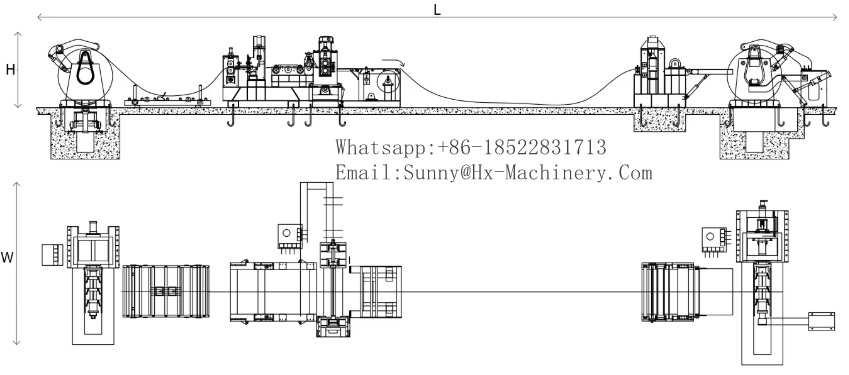

| Land occupation area | About 35m×5m |

This line mainly includes: hydraulic uncoiler, slitter and cutter, conveyor, hydraulic recoiler, or with roll forming machine,etc.

Some parts of the machine:

| A.Decoiler

Single cantilever structure bearing capacity 5Tons Support range:470-530mm hydraulic tension electric unwinding power:5.5KW frequency conversion and main motor 5.5KW Hydraulic pump 4KW

|

| B.Leveling

Hydraulic shovel head with two shaftsand total 11rollers(Up 5rows ,down 6rows ) roller diameter 90mm

|

| C.Slitting

slitting roll diameter 140mm-160mm Blade tool outer diameter 240-260mm Main motor power :7.5KW

|

| D.Damping

Double cylinder diameter 80mm Main frame use 10 mm thick iron plate welding Upper and Down iron plates with a thickness of 14 mm

|

| D.Collect waste

Power 2.7Kw*1set

|

| E. Hydraulic re-decoiler with coil car

|

Click to get more information about our machine and a more favorable price!

Some advantages of slitting machine steel:

| High Precision Cutting | Ensures consistent strip width and high-quality cuts for metal coils. |

| Increased Productivity | Fast, continuous operation boosts production capacity and reduces downtime. |

| Reduced Material Waste | Precise cuts optimize material use, minimizing waste and cutting costs. |

| Flexible Adjustments | Adjustable cutting width and speed to accommodate various material specifications. |

| Higher Automation | Automated operation improves efficiency, reduces manual intervention, and stabilizes production. |