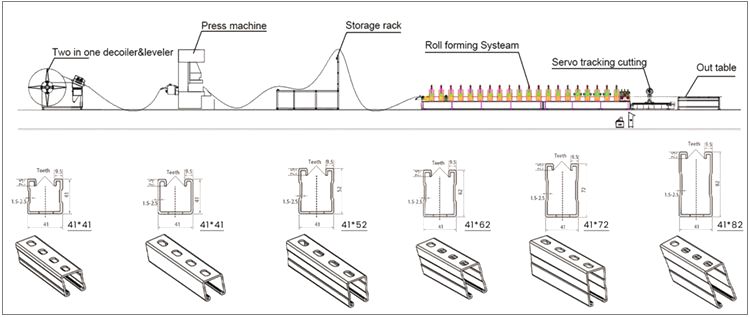

Solar structure machine unistrut c channel roll forming machine are production begins with coils of sheet metal (typically pre-galvanized steel or aluminum).The material is fed through a series of tandem rolling stations, where each set of precision rollers gradually bends and forms the metal into the final C-channel profile without removing any material. Key steps include:

-

Pre-punching: Slotted holes are precisely punched into the flat strip before forming, allowing for high-speed, accurate hole placement.

-

Progressive Forming: The strip passes through successive roll dies that cold-form it into the desired shape.

-

Cut-off: The continuously formed channel is cut to specified lengths.

This cold-forming process creates a strong, work-hardened product with excellent dimensional consistency and surface finish.

Solar structure machine capable of producing 41×21, 41×41, 41×52, 41×62, 41×72 and 41×82 profiles.

| Solar structure machine unistrut c channel roll forming main parameters | |

| Forming Rollers | 26rollers |

| Roller Material | Cr12 mold steel, vacuum quenching treatment, hardness HRC58–62 |

| Main Shaft Diameter | Finished diameter Ø80 mm |

| Main Shaft Material | 45# steel with quenching and tempering treatment |

| Motor Power | 18.5 kW *2 motors, K97 series hard-tooth gearbox |

| Transmission | Gearbox drive, coupled with universal couplings |

| Machine Frame | Cast iron archway 48 |

| Servo Punching | Non-stop servo punching,dual-module reverse punching |

| Cutting Method | Flying tracking saw cutting (with scrap) |

| Discharge Table | 3 m × 2 Pieces, roller-type support |

| Forming Thickness | 1.5-2.5mm |

| Forming Speed | 10-15m/min |

| Inverter | INVT brand |

| LCD Screen | Display Control Electric |

| Low-Voltage Electrical Components | Delixi or Chint |

| Hydraulic System | 11 kW × 2 pump station (for punching) 4 kW pump station (for cutting) 3 kW pump station (for pressing) |

| Bearings | Harbin Bearings |

| Reducer | Ruibofeng Reducer Co., Ltd. |

| Decoiler | Motorized decoiler with hydraulic expanding mandrel, load capacity 5 tons Inner diameter: 480–520 mm Max. outer diameter: 1600 mm |

| Leveling Section | 1.5 rollers 2. Leveling shaft diameter 70 mm 3. Material 40Cr high frequency quenching |

Solar structure machine more photos showing

Specialized & Emerging Applications For Solar Mounting Structures

| Carport Canopies | Dual-purpose structures that provide shade for vehicles while generating electricity. They require robust channels to span large areas and support significant loads. |

| Building-Integrated Photovoltaics (BIPV) | Systems where the mounting structure is an integral part of the building envelope, such as facades or skylights. |

| Agricultural Applications (AgriVoltaics) | Mounting structures are elevated to allow farming activities to continue underneath the panels. |

| Floating PV Systems | Specialized structures designed to support panels on bodies of water, such as reservoirs and lakes. They are highly corrosion-resistant. |