Solar strut roll forming machine :Solar Mounting Structure Strut Channel Rolling Forming Machine Is Designed To Make The Solar Mounting Structure Strut Channel In Batch Fully Automatic By Rolling Forming Principle.

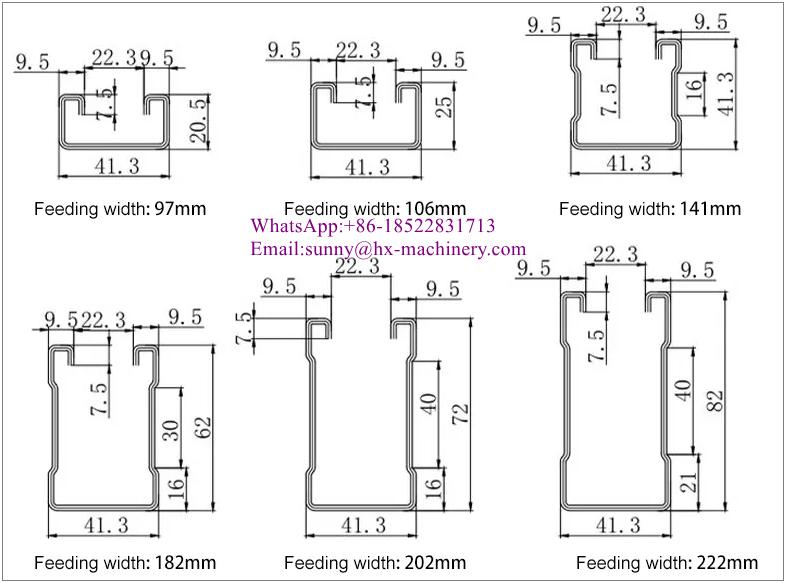

Profile drawing of solar channel roll forming machine

1, Material: zinc aluminum magnesium, galvanized steel coil strips, black steel strips can be.

2, Material thickness: 1.5-2.5mm

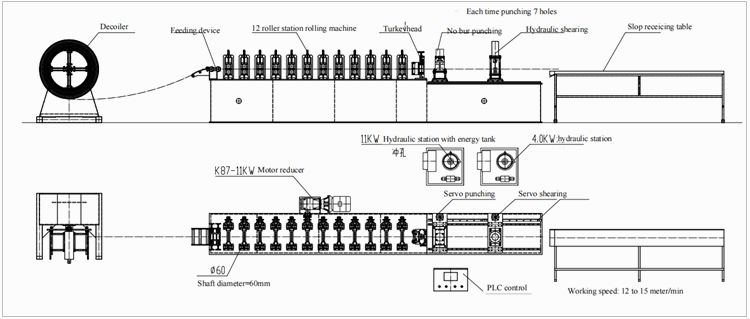

Solar mounting strut roll forming machine working flow

Uncoiling → Leveling → Roll forming → Punching → Flying saw non-stop cutting → Products receiving table

| Unistrut c channel roll forming machine main parameters | |

| Forming Rollers | 26rollers |

| Roller Material | Cr12 mold steel, vacuum quenching treatment, hardness HRC58–62 |

| Main Shaft Diameter | Finished diameter Ø80 mm |

| Main Shaft Material | 45# steel with quenching and tempering treatment |

| Motor Power | 18.5 kW *2 motors, K97 series hard-tooth gearbox |

| Transmission | Gearbox drive, coupled with universal couplings |

| Machine Frame | Cast iron archway 48 |

| Servo Punching | Non-stop servo punching,dual-module reverse punching |

| Cutting Method | Flying tracking saw cutting (with scrap) |

| Discharge Table | 3 m × 2 Pieces, roller-type support |

| Forming Thickness | 1.5-2.5mm |

| Forming Speed | 10-15m/min |

| Inverter | INVT brand |

| LCD Screen | Display Control Electric |

| Low-Voltage Electrical Components | Delixi or Chint |

| Hydraulic System | 11 kW × 2 pump station (for punching) 4 kW pump station (for cutting) 3 kW pump station (for pressing) |

| Bearings | Harbin Bearings |

| Reducer | Ruibofeng Reducer Co., Ltd. |

| Decoiler | Motorized decoiler with hydraulic expanding mandrel, load capacity 5 tons Inner diameter: 480–520 mm Max. outer diameter: 1600 mm |

| Leveling Section | 1.5 rollers 2. Leveling shaft diameter 70 mm 3. Material 40Cr high frequency quenching |

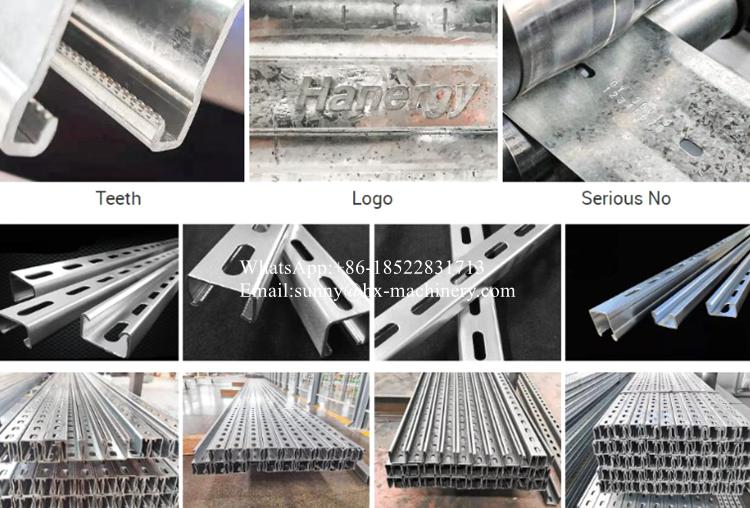

Solar strut roll forming machine photos showing

Specialized & Emerging Applications For Solar Mounting Structures

| Carport Canopies | Dual-purpose structures that provide shade for vehicles while generating electricity. They require robust channels to span large areas and support significant loads. |

| Building-Integrated Photovoltaics (BIPV) | Systems where the mounting structure is an integral part of the building envelope, such as facades or skylights. |

| Agricultural Applications (AgriVoltaics) | Mounting structures are elevated to allow farming activities to continue underneath the panels. |

| Floating PV Systems | Specialized structures designed to support panels on bodies of water, such as reservoirs and lakes. They are highly corrosion-resistant. |