steel coil slitter is a highly efficient industrial machine designed to precisely cut wide steel coils into multiple strips of varying widths, meeting the production needs of various industries. This equipment is widely used in industries such as steel manufacturing, automotive, home appliances, and construction, helping businesses improve production efficiency and reduce material waste.

| Main parameters of steel coil slitter | |

| Raw materials grade | Galvanized steel coil/Cold rolled coil/Color coil |

| Raw materials thickness | 0.3~3.0mm |

| Raw materials width | 1250mm |

| Raw materials inner diameter | Φ508mm/610mm |

| Raw materials outer diameter | ≤Φ1500mm |

| Raw materials coil weight | 5Tons |

| Slitting speed | 0~25m/min(During normal work) |

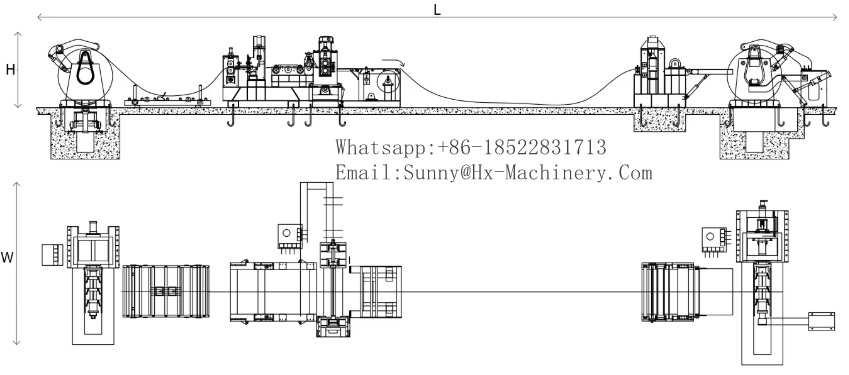

| Land occupation area | About 35m×5m |

This line mainly includes: hydraulic uncoiler, slitter and cutter, conveyor, hydraulic recoiler, or with roll forming machine,etc.

The machine utilizes a series of high-precision blade systems to divide large coils into narrower strips according to specified widths. It has an advanced control system that monitors and adjusts the slitting process, ensuring consistent width and smooth cuts.Additionally, the machine’s high speed and powerful drive system enable it to handle steel coils of various thicknesses and materials, catering to diverse production needs.

The machine features a strong build, simple operation, and low maintenance, making it ideal for various work environments.Whether in high-speed production lines or in small to medium-sized production workshops, the steel coil slitter plays a crucial role. With its intelligent design, the machine reduces manual intervention, enhances automation, lowers labor costs, and boosts production efficiency.

Overall, the steel coil slitter is a key piece of equipment for improving production line efficiency, ensuring product quality, and reducing production costs, making it an indispensable part of the modern steel processing industry.

Loading and shipment:

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

About Our Company – TIANJIN HAIXING

Tianjin Haixing is a professional manufacturer of cold roll forming machines.Our main products include roof roll forming machines, light keel roll forming machines, floor deck roll forming machines, purlin machines, leveling and slitting machines, metal fence roll forming machines, gutter roll forming machines, downspout roll forming machines, door frame machines, shutter door roll forming machines, highway guardrail roll forming machines, and other construction equipment.

We have extensive experience meeting the needs of different countries.This includes profile drawing, operation languages, thickness range, instruction manuals, installation, and after-sales online support. Our equipment features medium to high configurations, including top-brand PLCs, motors, frequency converters, long service life, remote control, multifunctionality, and energy-saving capabilities.

Click to get more information about our machine and a more favorable price!