Step beam machine:Our machines are engineered for superior performance in the production of step beams and tapered structural sections, our Step Beam Machine sets a new standard for efficiency, accuracy, and versatility. Designed to meet the rigorous demands of modern steel fabrication, it transforms raw beams into precise, ready-to-use components with unmatched consistency.

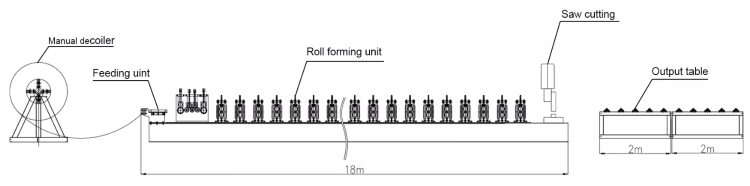

Production Process: Passive discharge—Leveling—Forming—Servo tracking cutoff—Discharge

Step beam machine: Drawing Model:Bottom:80-160mm technical details :

| Step beam machine manufacturers parameters | ||

|

||

| 1 | Equipment area | About 35*1.5*1.5m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 450-950 mm |

| 7 | Rolled strip thickness | 1.5(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Q235 cold rolled strip steel,galvanized coil |

| 9 | Rolling workpiece length | 2000-6000 mm |

| 10 | Produce speed | 6-12m/min |

| 11 | Motor explosion-proof grade | ExdIICT4 |

| 12 | Motor protection grade | IP55 |

| 13 | LCD display | Display Electric |

| 14 | Total installed capacity of equipment | About 25KW |

| 15 | Electrical low voltage control components Control system |

Delixi or Chint |

| 16 | Frequency system | INVT |

| 17 | Bearings | Harbin Bearing |

| 18 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 19 | Length Tolerance | ±1.5mm |

Step beam machine manufacturers detailed images for reference

| A.Uncoiler Decoiler

1. Maximum load-bearing capacity: 3T

|

| B.Leveling servo feeding machine

1.5 roller leveling

|

| C.Roll forming part

1. Shaft diameter φ65mm

|

| D.Discharging platform

1. 3m platform

|

Perforated step beam machine loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

Advantages of using a step beam machine line for beam roll production include:

| All-in-One Efficient Processing | integrates punching, drilling, cutting, and marking in a single setup, significantly boosting production efficiency. |

| High precision | ensures millimeter accuracy in hole positioning and cutting dimensions |

| Flexible | easily handling both high-volume standard parts and custom jobs. |

| Durable construction | Heavy-duty steel structure and industrial-grade components built for continuous, high-intensity operation, ensuring high reliability. |

| Saves material and cost | Optimized nesting and precise processing maximize material utilization |

| Safe and easy to use | Intuitive interface reduces the learning curve, while automated features minimize manual handling, enhancing job site safety. |