| Parameters of Tile forming machine | |

|

|

| Weight of machine | 5800kg |

| Size of machine | 7000*1900*2000mm |

| Rollers | 15 rollers |

| Chain length | 1 inch |

| Feed Thickness | 0.3-0.8mm |

| Feed width | 1200 |

| Cutter | Cr12 |

| Shaft diameter | 70mm |

| Material of the wheel | 45# Steel Chrome-Plated |

| Main motor power | 5.5KW |

| Pump motor power | 5.5KW(with fan) |

| Voltage | 380V, 50HZ, 3-phase electricity |

| Shear error | ±1.0mm |

| Cutting Method | Servo Cutting |

| Forming speed | 4-6m/min |

To get a favorable price and more machines of our machine factory!

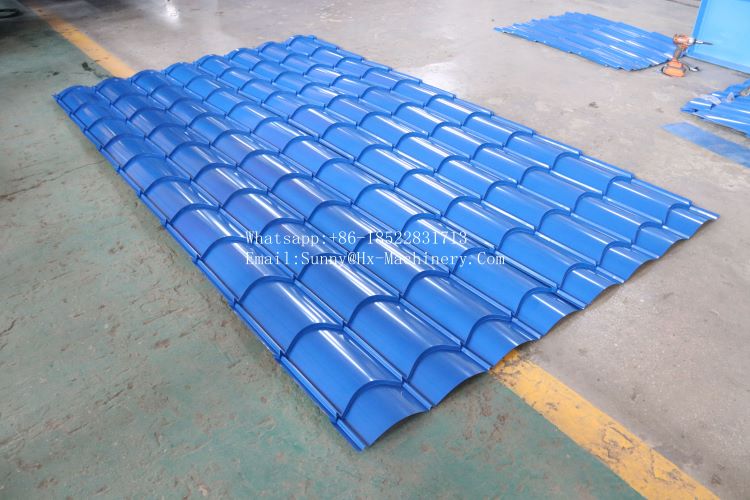

And our tile forming machine includes a whole automatic production line for producing Half-arc glazed tile. There are some Experience the Benefits of Full Automation:

loading and shipment :

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

We Provide Service:

Our roof tile roll forming machine is designed to provide efficient and reliable performance for your production needs. We offer technical support and services to ensure that your machine operates at its optimal capacity.

Our technical support team is available to assist you with any questions or concerns you may have about the installation, operation, and maintenance of the machine. We can also provide troubleshooting services to help you identify and resolve any issues that may arise.

In addition to technical support, we offer a range of services to help you maximize the productivity of your roof tile roll forming machine. These services include training and education programs to help your team use the machine effectively, as well as maintenance and repair services to keep your machine in top condition.

We offer worldwide shipping for our machine. The shipping cost and delivery time depend on the destination country. They also vary based on the transportation method chosen by the customer. We will provide all necessary documents and information to ensure a smooth and hassle-free delivery process.