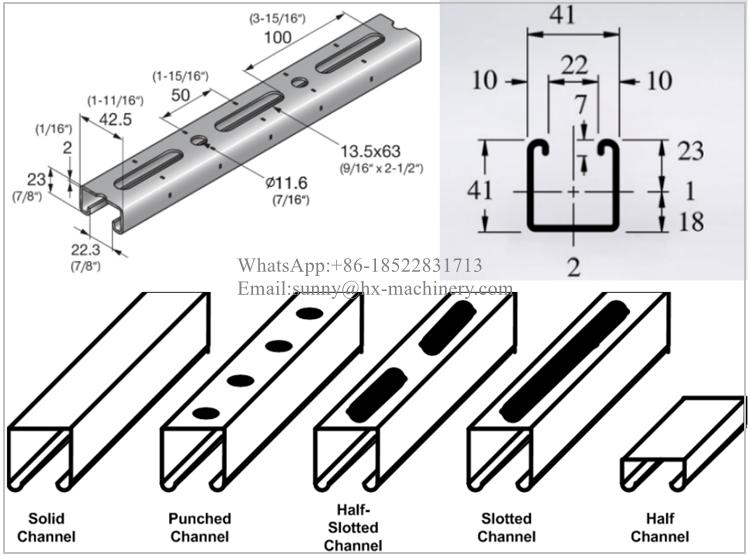

Unistrut c channel roll forming machine is high-efficiency forming equipment for producing strut channels.It can be used to form different sizes of strut channels with a width of 41-72 mm, adjustable according to different requirements. It is designed with a hydraulic decoiler and a forming speed of 10-15m/min.The weight of the machine is 6T, and it is characterised by high accuracy, high quality and high efficiency.

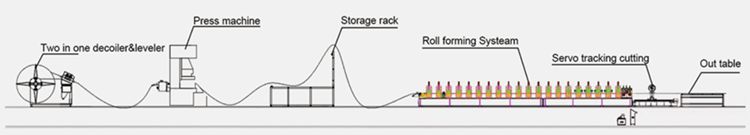

Punch press process flow:

Punching process: Unloading — feeding — forming — punching — cutting — discharging

This strut channel roll forming machine line can roll steel products with a maximum thickness of 2.0mm, and can produce steel products with size 41*21/41*41mm/41*52mm,thickness range 1.5(±0.03)~2.5(±0.03) mm

| Unistrut c channel roll forming machine parameters | ||

| 1 | Equipment area | About 30×2.5×2.0m |

| 2 | Equipment feeding direction | In left and out right |

| 3 | Voltage | 380V 50HZ 3Phase |

| 4 | Hydraulic oil | 46# hydraulic oil |

| 5 | Gear oil | 18# hyperbolic gear oil |

| 6 | Rolling strip width | 100-400 mm |

| 7 | Rolled strip thickness | 1.0(±0.03)—2.0(±0.03) mm |

| 8 | Rolled strip material | Galvanized steel strips |

| 9 | Rolling workpiece length | 6000 mm |

| 10 | Online punching production speed | 10-15 m/min |

| 11 | Production size | 41*21/41*41mm/41*52mm |

| 12 | LCD display | Display Electric |

| 13 | Total installed capacity of equipment | About 90KW |

| 14 | Electrical low voltage control components Control system |

Delixi or Chint |

| 15 | Frequency system | INVT |

| 16 | Bearings | Harbin Bearing |

| 17 | Reducer | Beijing Ruibofeng Reducer Co., Ltd. |

| 18 | Length Tolerance | ±2mm |

Strut channel roll forming machine photos showing

Solar strut channel roll forming machine loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

Why choose us?

| 1 | Complete after-sales service and technical support |

| 2 | Excellent performance and high-precision processing |

| 3 | High flexibility and versatility |

| 4 | Excellent reliability and durability |