Unistrut roll forming machine solar photovoltaic bracket

-

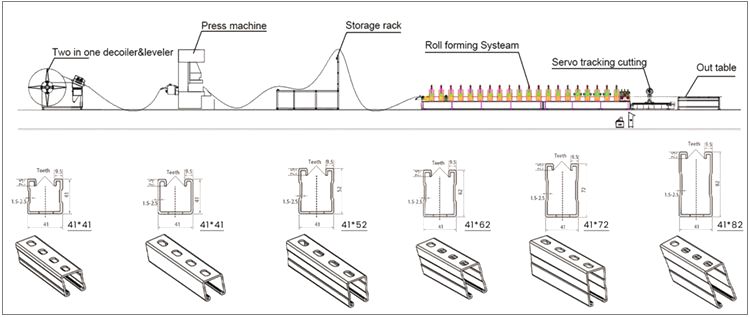

Multi-Profile Versatility : A single machine is configured to produce multiple channel sizes (41×21, 41×41, 41×51, etc.) with quick and straightforward adjustments. This flexibility allows manufacturers to meet diverse project specifications without investing in multiple dedicated lines.

Here is a professional English introduction and description for a solar channel roll forming machine capable of producing 41×21, 41×41, 41×52, 41×62, and 41×72 profiles.

Punch press process flow:

Steel Coil Decoiler –> Straightening Machine –> Punching Machine –> Roll Forming Machine –> Hydraulic Cut Off –> Run Out Table –> Finished product–> PLC Control

A. Decoiling: The raw material coil is loaded onto an automatic decoiler.

B. Leveling & Guiding: The metal strip is straightened and guided into the machine.

C. Pre-Punching (Optional): Holes and slots are punched flat before forming.

D. Roll Forming: The strip passes through the series of forming rolls, gradually shaping into the final C/U-channel.

E. In-Line Punching (Optional): Additional features can be punched post-forming.

F. Flying Cut: The continuously formed profile is cut to exact lengths.

| Photovoltaic bracket roll forming machine parameters | |

| Forming Rollers | 26rollers |

| Roller Material | Cr12 mold steel, vacuum quenching treatment, hardness HRC58–62 |

| Main Shaft Diameter | Finished diameter Ø80 mm |

| Main Shaft Material | 45# steel with quenching and tempering treatment |

| Motor Power | 18.5 kW *2 motors, K97 series hard-tooth gearbox |

| Transmission | Gearbox drive, coupled with universal couplings |

| Machine Frame | Cast iron archway 48 |

| Servo Punching | Non-stop servo punching,dual-module reverse punching |

| Cutting Method | Flying tracking saw cutting (with scrap) |

| Discharge Table | 3 m × 2 Pieces, roller-type support |

| Forming Thickness | 1.5-2.5mm |

| Forming Speed | 10-15m/min |

| Inverter | INVT brand |

| LCD Screen | Display Control Electric |

| Low-Voltage Electrical Components | Delixi or Chint |

| Hydraulic System | 11 kW × 2 pump station (for punching) 4 kW pump station (for cutting) 3 kW pump station (for pressing) |

| Bearings | Harbin Bearings |

| Reducer | Ruibofeng Reducer Co., Ltd. |

| Decoiler | Motorized decoiler with hydraulic expanding mandrel, load capacity 5 tons Inner diameter: 480–520 mm Max. outer diameter: 1600 mm |

| Leveling Section | 1.5 rollers 2. Leveling shaft diameter 70 mm 3. Material 40Cr high frequency quenching |

Unistrut roll forming machine solar photovoltaic bracket more photos showing

Solar structure making machine loading and shipment

| Host packaging | Naked in a container, or with a steel structure base and fixed with a wooden box or wooden frame |

| Electronic control system | Packed in protective film or placed in individual wooden boxes |

| Precision parts | They are usually placed in special wooden boxes and filled and wrapped with foam, paper scraps or oil paper. |

| Spare parts and tools | All spare parts are placed in wooden boxes |

| Packaging labeling | There are usually clear markings on the outside of the box |

Solar panel structure application

Main Applications: This equipment is specifically designed for solar photovoltaic (PV) mounting systems, used to produce critical support structural components. These mounting systems are widely used in various PV power plants and rooftop PV projects.