Upright rack roll forming machine is a specialized, automated production line designed for the high-volume, continuous manufacturing of the vertical support columns (uprights) used in pallet racking, storage systems, and heavy-duty shelving.This machine transforms coils of high-strength steel (typically 450MPa to 550MPa yield strength) into precise, roll-formed upright profiles with consistent, complex cross-sections.

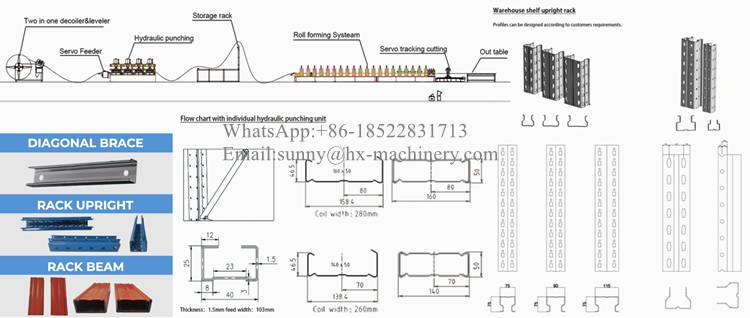

Rack upright roll forming machine working flow

Uncoiling → Leveling → Roll forming system→ Punching system→ Cutting system → Products receiving table

| Upright rack roll forming machinemain parameters | |

| Forming Rollers | 19rollers |

| Roller Material | Cr12 mold steel, vacuum quenching treatment, hardness HRC58–62 |

| Main Shaft Diameter | Finished diameter Ø90 mm |

| Main Shaft Material | 45# steel with quenching and tempering treatment |

| Motor Power | 11 kW *2 motors, K97 series hard-tooth gearbox |

| Transmission | Gearbox drive, coupled with universal couplings |

| Machine Frame | Cast iron archway 48 |

| Servo Punching | Non-stop servo punching,dual-module reverse punching |

| Cutting Method | Flying tracking saw cutting (with scrap) |

| Discharge Table | 3 m × 2 Pieces, roller-type support |

| Forming Thickness | 1.5-2.5mm |

| Forming Speed | 10-15m/min |

| Inverter | Delta brand |

| LCD Screen | Display Control Electric |

| Low-Voltage Electrical Components | Delixi or Chint |

| Hydraulic System | 5.5Kw |

| Bearings | Harbin Bearings |

| Reducer | Ruibofeng Reducer Co., Ltd. |

| Decoiler | Motorized decoiler with hydraulic expanding mandrel, load capacity 5 tons Inner diameter: 480–520 mm Max. outer diameter: 1600 mm |

| Leveling Section | 1.5 rollers 2. Leveling shaft diameter 70 mm 3. Material 40Cr high frequency quenching |

Upright rack roll forming machine each part photos showing

Specialized & Emerging Applications For shelf storage rack cold roll forming machine

| Shelf Panels | This equipment produces shelf panels for supermarkets, warehouses, and other similar applications. It can process shelves of varying widths. |

| Uprights/Posts | The vertical support columns for manufacturing shelving are typically punched in-line to allow for later height adjustments. |

| Rack Beams | Produces main load-bearing components for connecting columns, load-bearing shelves, or pallets. |

| Pallet Racking | This type of racking is used to manufacture pallet-bearing racks, drive-in racks, and similar systems. These racks have high load-bearing capacity and high storage density. |

| Tool Racks | Specialized storage equipment for manufacturing heavy molds that can withstand hundreds of kilograms to several tons. |